LOCATION – NORTH INDIA, WESTERN UP HIGH TENSION INSULATOR MANUFACTURING PLANT USING DESMA MOULDING MACHINE

SYNOPSIS – An insulator manufacturing company was using Desma molding machine and was experiencing failure of pump and machine downtime due to contamination in hydraulic oil.Most manufacturers would consider void warranty -since oil was not being maintained to desired ISO codes.

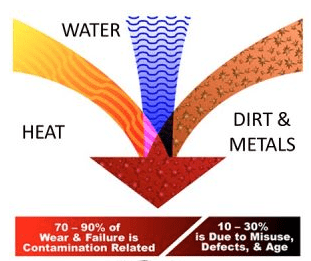

PROBLEM– No online or dedicated ultra-fine filtration system was provided by a machine manufacturer or purchased by the owner that could stop ingress and routine contamination of oil.

Since The Tolerance Of Pump And Valves Was Critical -Oil Cleanliness To Minimum Standard Requisite ISO Code-16/14/11 Was Not Being Maintained.

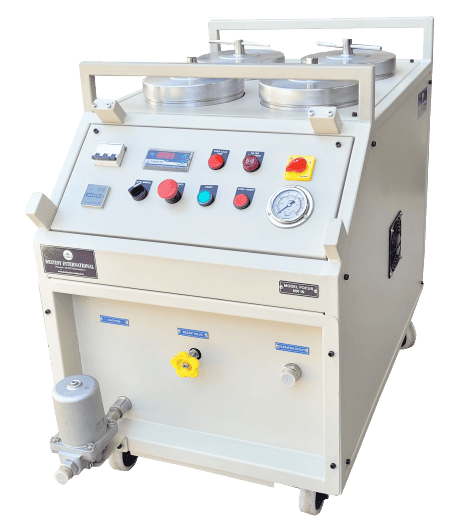

SOLUTION– Destiny makes, dedicated filtration unit-Model-EP-200 in was installed on the hydraulic tank. Oil was monitored using an online particle counter.

Filtration Unit-Model-EP-200

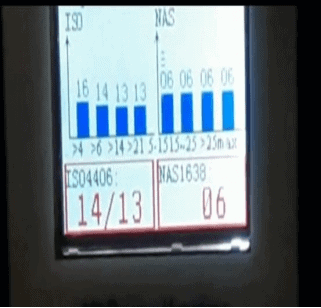

ONSITE COUNT-ISO CODE 14/13 NAS 6

ONSITE COUNT-ISO CODE 14/13 NAS 6

DESTINY-ULTRAFINE OIL FILTRATION SOLUTION UNIT

EP 200 IN- OIL CLEANING MACHINE also remove routine moisture from oil . In Case a higher quantity of water needs to be separated from the oil – Low Vacuum Dehydration machine is advised.

In the context of hydraulic oil filtration, insulator injection molding and ultrafine filtration can play important roles in maintaining the performance and longevity of hydraulic systems.

In hydraulic systems, the oil used as a fluid must be free of contaminants, such as particles and moisture, in order to maintain the efficiency and reliability of the system. This is where ultrafine filtration comes into play. By removing ultrafine particles from the oil, the risk of damage to the system’s components and reduced efficiency due to contaminants is greatly reduced.

Insulator injection molding can be used in hydraulic systems to produce custom-molded insulators for components such as electric motors and other electrical components. The insulators must be able to withstand the high pressures and temperatures present in hydraulic systems while also providing effective electrical insulation.

When designing a hydraulic oil filtration system, it’s important to consider both the insulator injection molding and ultrafine filtration components in.

In some cases, the two fields may intersect, such as in the production of insulators for use in filtration systems. In such cases, the insulator material must not only provide electrical insulation but also be compatible with the fluid or gas being filtered and be able to withstand the high pressures and other demands of the filtration process.

Don’t change your oil, filter it!

Can’t find what you’re looking for?

Contact Us for overarching Solutions

Destiny standout as the most reliable supplier & Manufacturer exporter of Hydraulic oil filtration machine, Hydraulic Off-Line Filtration Units, oil filtration machine in India, Hydraulic Oil Filtration Machine, Hydraulic Oil Cleaning System, Hydraulic Oil Cleaning System, Hydraulic Oil Cleaning, Hydraulic Oil Maintenance System, Oil filtration systems manufacturer, Oil Cleaning Machine, dedicated filtration unit

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content

We respond quickly to emergency outages and situations – call us at (783) 878-1100

sdc1888 , water glycol filter SDPC 2088, cartridge sdc 1888

Insulator Injection Moulding

Insulator Injection Moulding