Desiccant Breathers Filter separates contaminant such as dirts & moistures from air entering machinery, sumps & different reservoirs.Moisture and dirt originating outside of machine system are major cause of equipment or machinery loss of use.Moisture originating outside of machine causes corrosion and mechanical wear along with dirt. Moisture can cause changes in viscosity deplete additives and cause sludge formation.

Dessicant is a hygroscopic (material that attracts and hold water molecules) substance.

A desiccant breather filter is a device used to remove moisture and contaminants from the air entering equipment such as gearboxes, transformers, and other enclosed systems. The filter typically contains a desiccant material, such as silica gel, which absorbs moisture, as well as a filter element that removes particles and other contaminants. The desiccant material is usually contained in a replaceable canister, which can be replaced when it becomes saturated with moisture. These breathers are commonly used in industrial settings, particularly in environments where moisture and high humidity can cause problems for equipment.

A Desiccant Breathers Filter equipment installed on a machine to prevent ingress of moisture and contaminants.

Gearboxes, pumps and reservoirs take in and take out i.e. “breathe” when air in the empty space expand and shrinks due to temperature changes and oil level changes in the case of hydraulic systems-incoming fluid displaces air or when hydraulic components are running. Each time equipment exchanges

air -dirt, debris and moist liquid vapors are brought in, contaminating the lubricant and damaging the equipment in process. 50% lubricant contamination comes from outside machinery and most machines are designed to breathe,

Desiccant Breathers Filter

All Types & Models

It is better to stop contaminants at the source “Breather”

How to choose a Desiccant Breathers Filter

There are multiple reasons that you need to consider before choosing a Desiccant breather:

| MODEL | H20 ADSORBTION | CONNECTION SIZE | FLOW RATE | COMPATIBILTY GEAR/HYD/MINERAL/SYNTHETIC |

| BC 1 | 50 ml | 3/8 MULTIFIT | 4.16 cfm | YES |

| BC 2 | 118 ml | 1’’MULTIFIT | 16 cfm | YES |

| BC 3 | 220 ml | 1’’MULTIFIT | 16 cfm | YES |

| BC 4 | 353 ml | 1’’MULTIFIT | 16 cfm | YES |

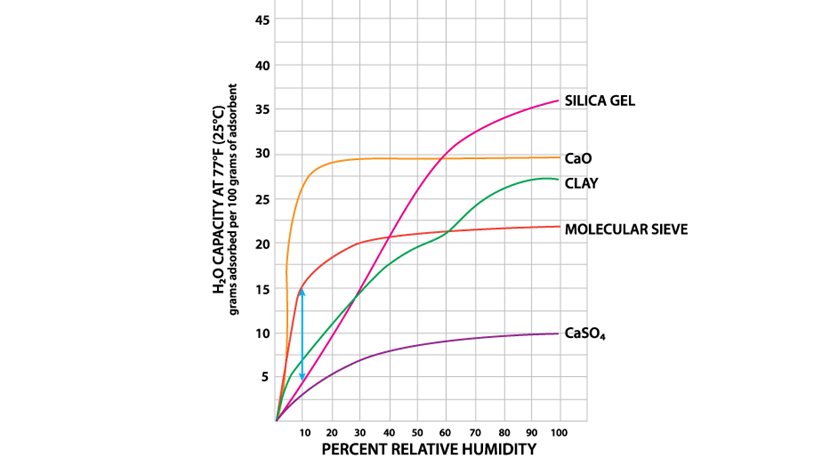

ADSORPTION(H20) RATE OF VARIOUS ADSORBENTS GRAPHICAL

- What is the environment?What is the application?

- What is the average and maximum airflow rate?

- What is the maximum reservoir capacity?

- Is the operation intermittent or continuous?

APPLICATION AREAS FOR BREATHER

1. DISPOSABLE STATIONARY APPLICATIONS:

This includes gearbox, fluid reservoir, transformer, pump & storage tank.

2. LIMITED SPACE APPLICATIONS:

Applications with less space include gearbox, drum, totes and small oil container.

- HIGH HUMIDITY/DUST APPLICATIONS:

Paper mills, wash down area, steam clean place & mine quarries are extremely best example of high humidity applications. - HIGH VIBRATION APPLICATIONS:

Products such as cranes, railroads maintenance vehicles, constructions vehicles & off – road trucks could all benefit from a breather designed for vibration and mechanized shock. - EXTREME ENVIRONMENT APPLICATIONS:

Exposed equipment such as windmill, wind power turbines, mining equipment, farm equipment and off-road vehicles are common examples of equipment operating in extreme environments. - CAUSTIC FUMES/GASEOUS APPLICATIONS:

Airport boarding jet airways, hydraulic fluid places, forklifs and baggage haulers are common examples of this application.

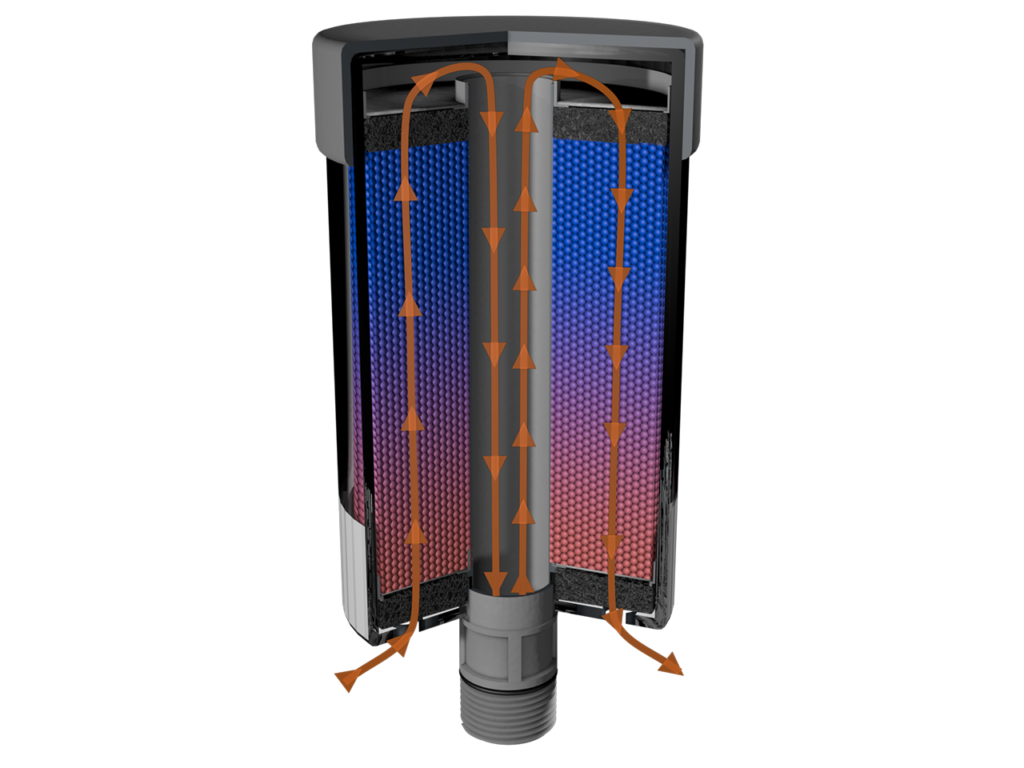

Desiccant breathers vary in design and construction. Some work by using a three-stage design to help ensure the interior of your equipment stays clean and dry. Incoming air is cleaned and dehydrated through an initial solid particle filter, a container of silica gel and another solid particle filter. As our diagram shows desiccant breathers work like this:

- As the machine breathes, contaminated air enters the desiccant breather and goes through the first solid particle filter. This is typically filtering out particles two microns or greater.

- Next, the outside air is dehydrated through a container of silica gel desiccant which extracts the water vapor in the air.

- Finally, the outside air passes through a third two-micron solid particle filter at the bottom of the desiccant breather.

Don’t change your oil, filter it!

Can’t find what you’re looking for?

Contact Us for overarching Solutions

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content.