OBJECTIVE-HOW TO ASCERTAIN OIL FILTRATION PRINCIPLE /TECHNOLOGY TO BE USED

For industrial hydraulic and lubrication oils, the following three principles are generally considered for use -before any system is put in use.

1) Electrostatic Systems

2) Filter Media-Based Systems

3) Depth Filters

4) High Flow Surface Filters

5) Centrifugal Systems

ELC’S OR ELECTROSTATIC LIQUID CLEANERS

Electrostatic oil filtration was a pioneer in introducing the concept of oil filtration, and the end-user became well accustomed to the practice of filtering oil-whether it was done by outsourcing as service job work or by purchasing ELC filtration machines.

As traditional wire mesh filters and conventional filters were in use in industrial machines, the concept of ELC filtration systems introduced by the Japanese was well appreciated by the industry, and it got recognized by excellent service and oil patch testing done by the manufacturers of ELCs and service providers.

The benefits were evident to the end-user, since lesser oil-related issues made justification for oil cleaning. Portable easy to maneuver oil filtration machine -set a trend for oil maintenance.

One major drawback was the incompatibility of the moisture in oil and the electrostatic principle.

Which till today is a major concern if ppm of moisture increase above 500 for ELCs.

DEPTH AND SURFACE FILTERS

USED IN OIL FILTRATION TROLLEY OR BYPASS /PRESSURE ONLINE FILTER

CENTRIFUGAL FILTER PERFORMANCE

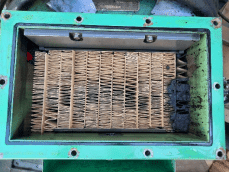

CELLULOSE DEPTH FILTER MEDIA

Japanese also pioneered filter media, especially the Depth filtration technology which was comparatively simpler but overcame the drawback that the electrostatic systems faced.

A depth filter was smarter to handle dirtier oils, remove moisture from oil and give equal if not better polish to machine oils.

The depth filter technology was not well explained to the end user since less work was done in this aspect as compared to ELC which being the first had placed itself well with the end-user.

Overtime depth filters were introduced as permanent installations on the most hydraulic machine of makes made in Japan, Taiwan, China, the US, etc.

As end-user saw the depth filtration systems as standalone units installed directly on machines as bypass units without any electrical consumption as TRANSFERABLE OR MOVEABLE OIL FILTRATION UNIT and a mechanical gauge to monitor the status of filter, the benefit was well improved than the ELCs.

Most moulding machines, casting machines, and hydraulic presses had a canister or few that were maintain oil cleanliness in bypass or motorized kidney loop 24×7.

They were rightly called silent performers.

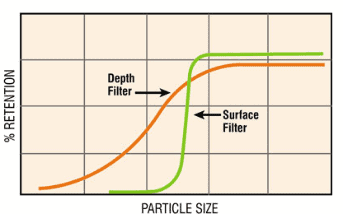

SURFACE MEDIA FILTER

Surface high flow filters have been used as online high-pressure filters with robust strength fiberglass depth media and follow the principle of the increased number of passes due to higher flow rate and absolute beta ratings.

These are well used in transfer units or flushing applications also.

These have been pioneered by the EU primarily due to their expertise and R &D.

CENTRIFUGAL FILTRATION

Centrifugal filtration systems were exclusive for high volume and moisture-related applications such as turbine oils in cement/power/marine applications.

For industrial hydraulic oils, the level of oil cleaning is not achievable by centrifugal systems hence it has not been a preference in the industrial sector.

Quality centrifugal systems due to their pricing concerns do not fit in the ROI of the segment end-user.

All the more it becomes tedious and unencouraging for the end user to clean the centrifugal bowl frequently.

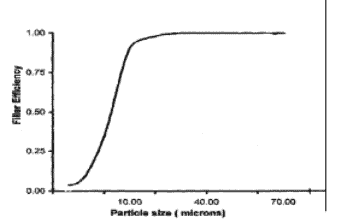

ELECTROSTATIC ELC PERFORMANCE GRAPH

Comparison Of Oil Filtration Systems For Industrial Hydraulic/Mineral Oils

Comparison—Electrostatic Elc /Depth Filter Media/Centrifugal/Surface Filter

CRITERIA | ELECTROSTATIC FILTRATION | DEPTH FILTRATION SYSTEMS | SURFACE FILTER | CENTRIFUGAL FILTERATION |

|

|

|

| |

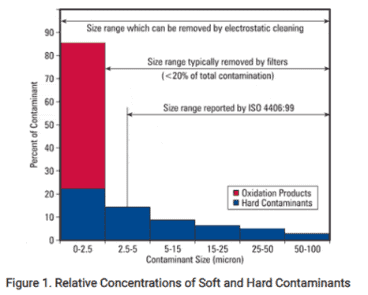

EFFICIENCY FOR DIRTY OIL NAS 11 AND ABOVE | LOW | HIGH | LOW | VERY HIGH |

EFFICIENCY IN CLEANER OILS BELOW NAS 11-8 | HIGH | HIGH | HIGH | LOW |

EFFICIENCY IN ULTRA FINE FILTRATION BEOW NAS 7 | HIGH | HIGH | HIGH | VERY LOW |

PERFORMANCE -MOISTURE LESS THAN 500 PPM | HIGH | HIGH | HIGH | NA |

PERFORMANCE-MOISTURE ABOVE 500 -2000 PPM | POOR | HIGH | POOR | NA |

COST OF CLEANING/LTR | LOW | LOW | LOW | VERY LOW |

COST OF MICROPROCESSOR | VERY HIGH | NA | NA | NA |

COST OF TRANSFORMER REPLACEMENT | VERY HIGH | NA | NA | NA |

COST OF PUMP | SAME | SAME | SAME | SAME |

OPERATION OF MACHINE AVERAGE TECHNICIAN | TOUGH TO UNDERSTAND CONTROLS/PROCESSOR | EASY | EASY | LABOUR INTENSIVE/FREQUENT CLEANING |

EASE OF FILTER/COLLECTOR CHANGE | TIME CONSUMING | EASY | EASY | TIME CONSUMING |

SAFETY SCALE 1-10 | 8 | 9 | 9 | 10 |

ELECTRICAL CONSUMPTION | COMPARITIVELY MORE | STANDARD | STANDARD | STANDARD |

SELF SERVICE BY ENDUSER | COMPARITIVELY TOUGH | EASY | EASY | EASY |

OEM INSTALLATIONS | NO | YES | YES | NO |

BRAND VALUE | HIGH | MODERATE | MODERATE | LOW |

Don’t change your oil, filter it!

Can’t find what you’re looking for?

Contact Us for overarching Solutions

Destiny standout as the most reliable supplier manufacturer exporter of hydraulic oil filtration machine, hydraulic off-line filtration units, oil filtration machine in India, hydraulic oil filtration machine, Hydraulic Oil Filtration Machine Manufacturer In India, portable oil filtration systems, portable oil filtration machine, electrostatic oil filtration machine manufacturer and supplier in India, low vacuum dehydration machine, coolant sump cleaner, Hydraulic Oil Filtration Machine Manufacturer In India,Industrial Hydraulic Oil Filtration

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content