Hydraulic Oil Filtration Machine & Oil Filtration Equipment in India

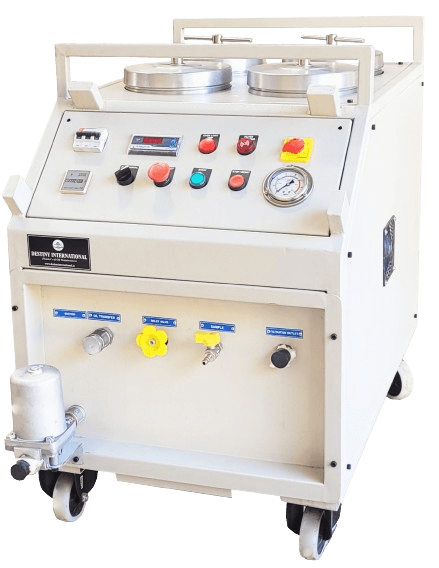

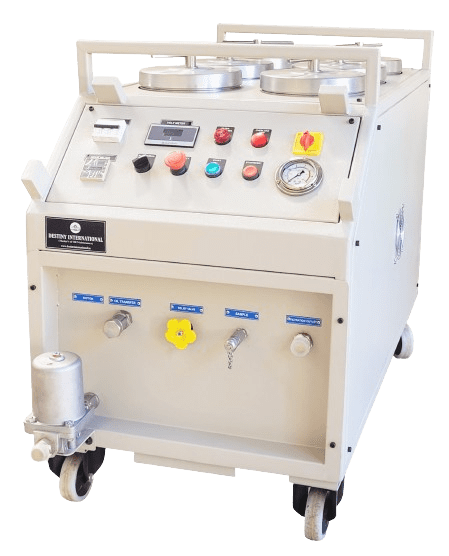

Destiny’s® FD/FP Series Oil Filtration Systems are high end technology machines popularly used for Ultra-Fine Stage Filtration (fine solid particle removal) of lubricating and hydraulic oils.

Discover our high-quality products designed to meet your specific needs

Our range includes advanced filtration systems, cutting-edge oil cleaning solutions, and reliable maintenance equipment.

Each product is meticulously engineered to deliver superior performance, ensuring optimal efficiency and cost-effectiveness for your operations.

Our Oil Filtration Machine is a multi-purpose fluid cleaning machine that can clean most oils such as hydraulic oil, gear oil and many soluble oils and fluids. More than 85% of hydraulic oil failures are caused by contaminants in the oil.

Meeting Our Hydraulic Systems’ High Oil Purification Standards

Our Products

- Oil Filtration Machines

- Hydraulic Oil Filtration Systems

- Electrostatic Liquid Cleaning (ELC) Machines

- Elc Collector-25c,50c,100c

- Low Vacuum Dehydration Unit (LVDH)

- Filter Cartridges

- Coolant Sump Cleaner

- By-Pass Filters

- Oil Transfer Unit

- Electrostatic Oil Filtration Machine

- Oil Analysis Equipment

- Contamination Cleaning Kit (CCK)

- Oil Skimmer

- Dedicated Motorised Filtration Unit

- HF series Filtration System-45LPM-54LPM

- Magnetic Oil Filtration Unit

- Highly Effective Filter Media

Applications:

- Plastics Injection Moulding Machines.

- Steel Plant & CNC Machine Tools

- Bearing Lubrication System.

- Hot Press in plywood Industries

- Cement & Ceramics Industries.

- Earth moving, Construction & Mining Equipments.

- Aluminum Extrusion & Die Casting Machines.

- Aviation, Railways & Automobiles.

- Power Transmission Plant

- Power Generation. Gase, Hydro & Thermal

- Hydraulic Press & Hot/Cold Steel Mills.

How Important is Fluid Filtration in a Hydraulic System?

A hydraulic system is a complicated network of components, hoses, valves, and piping which are commonly found in any heavy-duty machinery. These systems may be diverse in terms of how they operate, but their basic operating principle remains the same – generating force through non-compressible fluids.

Hydraulic systems are commonly found in the steering wheels of a vehicle or applications used for heavy lifting of weights. A hydraulic system is a mechanical process, therefore, it’s vulnerable to regular wear and tear. Some of its components like springs and seals become loose due to leakages and poor fluid filtration. Fluid contamination is considered to be one of the main reasons for the failure of hydraulic systems according to industry experts.

Selecting the right kind of hydraulic oil filter cart is very important. There are lots of variants available in the market right now. It’s advised to consult your original equipment manufacturer OEM before buying a certain fluid as it depends on the kind of device you have. For most of the applications, petroleum-based oil fluids are generally recommended by the experts. Water-oil emulsions, water-glycol, and synthetic hydraulic fluids are also utilized for fire-resistant fluids

Destiny’s ® Hydraulic Oil Filtration Systems Cleaning Result :

Why Choose Destiny’s ® Hydraulic Oil Filtration Systems?

- Ultra-Fine Filtration (0.1 Micron) : Our filtration systems are engineered to remove even the tiniest particles—down to 0.1 micron—ensuring your hydraulic oil remains free from contaminants that could cause wear and tear on pumps, valves, and other critical components. This level of precision helps prevent costly downtime and extend the life of your machinery.

- Enhanced System Performance : Contaminated hydraulic oil is one of the leading causes of equipment failure and efficiency loss in manufacturing. By keeping your hydraulic fluid clean and free from particles, our systems help to optimize the performance of your equipment, maintain consistent pressure levels, and reduce system breakdowns. This is essential for maintaining the high throughput and reliability that plastics component manufacturing demands.

- Minimized Maintenance Costs : Regularly filtering out contaminants can significantly reduce the frequency of expensive maintenance work and repairs. With our hydraulic oil filtration systems in place, your machinery will run more efficiently, requiring fewer maintenance interventions and lowering your overall operational costs.

- Improved Product Quality : Hydraulic fluid contamination can lead to irregularities in the molding process, affecting the quality and consistency of your plastic components. By ensuring that your hydraulic systems are operating with pure, contaminant-free oil, you can achieve better control over your production process and ultimately improve the quality of your final products.

Durable and Reliable Design : Built for the demanding environments of plastics manufacturing, our filtration systems are rugged, easy to maintain, and engineered for long-term use. Whether you operate injection molding machines, blow molding systems, or extrusion lines, our systems are designed to seamlessly integrate into your existing setup and provide lasting protection.

Customizable Solutions :

We understand that every plastics manufacturing operation is unique. That’s why we offer customizable filtration solutions to meet your specific needs. Whether you need filtration systems for individual machines or a centralized solution for multiple production lines, our team works with you to provide a tailored solution that fits your operations perfectly.

Why Choose Destiny’s ® Hydraulic Oil Filtration Systems?:

- Extended Equipment Life : Reduces wear on pumps, valves, and seals.

- Lower Operational Costs : Decreases maintenance expenses and downtime.

- Enhanced Efficiency : Keeps hydraulic systems running smoothly with consistent pressure.

- Reduced Contamination Risks : Prevents debris and contaminants from entering critical hydraulic components.

- Environmentally Friendly : Helps reduce the need for frequent oil changes, lowering your overall environmental impact.

Salient Features:

- Filter Media-wood pulp paper

- Filter efficiency 0. 1 microns

Salient Features:

- Consultation – Assess and identify the right system for you.

- Water Filtration – Remove 100% water contamination. Water contamination can reduce the life of machinery by more than 50%.

- Particle Filtration – Remove contamination down to 0.1 micron (3 absolute)

- Oil Analysis Reports – Enable us to assess the effectiveness of your filtration, cooling systems and identify failing components.

- Improvement Plan – Practical suggestions to help you reduce contamination before it happens.

Mistakes by Customers:

- Changing the filters on hours… .

- Only change when 80% of the dirt holding capacity has been reached.

- Running too hot… .Keep it cool! Stay below 60˚C for hydraulic oil!

- Disregard the start-up check list… .

- Always act according to your machines’s start-up check list!

- Changing the oil on hours…

- Keep it clean and have it analyzed first!Using the wrong oil… .

- Check what viscosity grade fits your machine requirements the best!

- Wrong filter locations… .

- Avoid a suction strainer at the pump inlet!

Steps to maintain a functional hydraulic oil filtration machine:

- The area around the reservoir must be neat and clean.

- Conduct proper flushing of all systems before preliminary starting.

- When the new equipment achieves its break-in period, change fluids and hydraulic filters.

- The reservoir must have a quality breather attached to it.

- Make sure that the fluid being added must reach the exact specifications during addition.

- Filter all the fluid down the reservoir periodically with the help of an A-Grade hydraulic filter cartin the form of a kidney loop.

- Perform fluid analysis tests regularly especially after suspecting contamination.

- Ensure that your team utilizes standard Beta 1000 elements in every filter housing, and replace them when required.

- Make sure that the hydraulic hoses are plugged in well while repairing the system.

- Always repair leakages as early as possible.

Destiny’s® Ultra-Fine Oil Filtration Machine :

How to change a Destiny’s® filter

Destiny's Hydraulic Oil Filtration machine (Models) :

For all of our services, we bring a Hydraulic Oil Filtration Machine, Hydraulic Oil Filtration Unit and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance (achievement of specified ISO cleanliness levels and moisture content)

Destiny’s® Ultra-Fine Oil Filtration Machine-Unique Filtration Stages

1st stage

Big particles are retained on the top of the filter

2nd stage

Small particles are trapped in the mid stage of the filter element

3rd stage

The smallest particles are trapped in the lower and compressed part of the filter

A revolutionary 3-in-1 element design allows to guarantee absolute filtration effectiveness.

The filter design forces the oil to flow through filter media and creates 3 distinct stages of filtration. The lower part is compressed by a base paper, creating an even finer filter medium.

- Big particles stay on top of the element

- Smaller particles are captured in the upper non-compressed part

- The smallest particles are captured in the lower compressed part

The filter becomes an excellent diagnostic tool as big PARTICLES are retained on top.

The cellulose filter media absorbs WATER drops and therefore dries the oil to less than 100 ppm.

The industry’s thickest filter, results in the unique ability to absorb and remove oil oxidation residues, well known as VARNISH, or sludge deposits.

Don’t change your oil, filter it!