Water contaminant in oil

Water can damage oil properties and reduce life of hydraulic machinery by alarming 50%. Due to low tolerance in modern machinery the continuous pressure vacuum conditions cause the moisture to expand and explode on the walls of metal surface causing wear and continuous blasting of inner surfaces with particles and vacuum explosions.

Corrosion into small microscopic pores will cause fatique and wear of equipment. Water increase oxidation in presence of iron and copper as catalyst and the acidity of oil is increased and with TAN number increases to >1 leads to oil changes expense. Constant changes in temperature leads to condensation and corrosion and addition of contaminants in system.

Oil analysis is important to maintain the mechanical integrity of system and to prevent damage to components. Oil’s TAN will increase with time or if exposed to high temperatures and water presence.The oil becomes oxidised (high temperatures will cause oil molecules react with the oxygen within the air). Oxidation will severely affect oil’s ability to save internal components and can also hinder the viscosity.

How to Measure Water In Oil

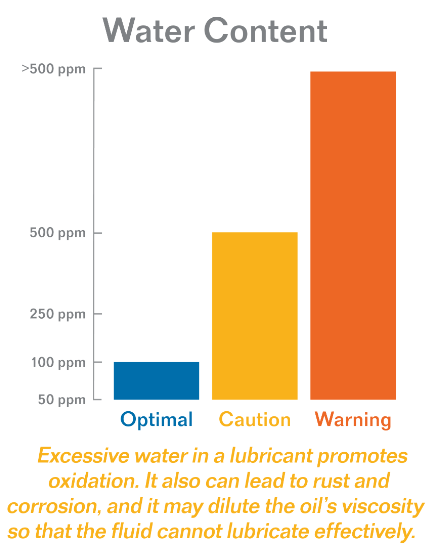

Water is perhaps the most harmful of all contaminants with the exception of solid particles. While the presence of water is often overlooked as the primary root cause of machine problems, excess moisture contamination can lead to premature oil degradation, increased corrosion and increased wear.

Moisture, upon contaminating hydraulic and lubricating oils, has a degrading effect to both the lubricant and the machine itself. While some additives adsorb to the water and are removed when the water separates from the oil, others are destroyed by water-induced chemical reactions. Water also promotes oxidation of the oil’s base stock, causes rust and corrosion of machine surfaces, and reduces critical, load-bearing film strength. Essentially, water represents a real risk to equipment and should be aggressively controlled.

Removing Water Contamination from Oil

Water contamination is often called the scourge of the machine. An ongoing battle ensues between lubrication technicians in the wet process industries like pulp and paper, in outdoor machinery applications like construction and mining, and where frequent machine wash downs occur such as food processing.

Its effects are not limited to these industries, however. Water contamination rears its ugly head in almost every plant and industry.

Water affects both the oil and the machine. It promotes oxidation of the lubricant’s base oil and washes out some additives which are attracted to water. Later, water will typically separate to the bottom of the sump. It hydrolyzes (chemically attacks) additives, which compromise their performance, and in some cases, produces highly corrosive by-products.

A water-degraded lubricant cannot fully lubricate and protect the machine, which leads to excessive wear and failure. Water also attacks the machine directly.

Companies spend much money on installing filtration units to counter particle contamination but never take preventive measures towards water contamination. Water is a worse and silent killer for the life of machinery as it slowly degrades the oil properties, and one only gets to know about it when the machine fails pre-maturely. In this article, we will try to understand the basics of Water Contamination. We will also try to answer the following questions.

1. What water does to oil properties?

2. Can we see water contamination as soon as it starts?

3. What to do if our oil is contaminated?

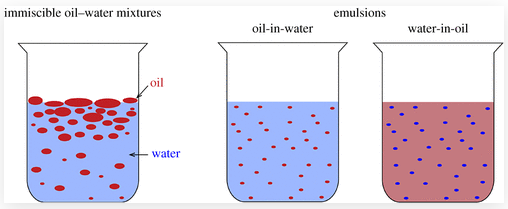

There are three phases in which water can exist in oil, i.e., dissolved water, emulsified water, and free water.

- Dissolved Water: It is characterized by individual water molecules dispersed throughout the oil. Water can remain in a dissolved state, and hence difficult to understand the contamination at this stage.

- Emulsified Water: When the oil gets saturated with water, it starts to exist as a suspension in oil-like microscopic droplets giving the oil a milky appearance and is called emulsion.

- Free Water: When the level of oil in water increases further, it leads to the separation of oil and water called Free water.

For a lubricant, the most important property is its viscosity. As the water starts to mix with lubricant it starts to alter the viscosity and hence impacts the film strength which is essential in maintaining equipment reliability by keeping moving parts away from each other. Water contamination also impacts the chemical properties of the base oil by acting as catalyst oxidation and aeration. This also leads to the appearance of sludge and varnish, which leads to premature failure.

Water contamination also leads to Hydraulic Pump Cavitation in machines:

Pitting inside of the machine; as the water droplets burst under pressure and high temperature, creating microfractures on the machine’s surface.