Low Vacuum Dehydration Machine (lvdh machine)

Low Vacuum Dehydration Machine (lvdh machine)

The Low Vacuum Dehydration (LVDH Machine ) technique is mainly used for separating moisture content from the oil which is present in three forms:

a) Dissolved Form

b) Emulsified Form

C) Free form

- Very fast and highly effective water removing device, meant for high duty applications.

- Easy full automatic operation.

- Removes water, moisture and air bubbles: dissolved water: 80%, free water: 100%, air bubbles: 100%

- Viscosity range from 10 ~ 600 cSt.

- Oil temperature from 15°C ~ 60°C.

- On demand, all systems can be supplied by customer requirement.

Working Principle of Low Vacuum Dehydration machine :

The heating of hydraulic oil is performed indirectly and then that is poured into a vacuum chamber where it is scattered into a very thin layer of film thereafter it vaporizes & gets dissolved with gases at low temperature. How do separate water from oil? Now both air and gases that are derived from the previous process are now left to condense so that it gets separated from the oil. Our ultimate goal of heating oil indirectly at low temperature is to ensure that there is no burn off, hence no oxidation and no additional depletion of oil.

Features:

- Fully automatic operation.

- Ultimate water removal through oil recirculation – to zero-free water content or to 50 % below saturation level.

- Reduces water content in a single pass by 0.25% – 1.5% depending on inlet oil temperature.

- Removal of soluble gases and air.

Oil Condition for LVDH Machine:

Viscosity: Not above CST 320 max

Water content: Not above 20,000 ppm

Oil dirt level: Not above NAS 12

RESULT

- Hydraulic oils

- Turbine oils

- Lubricating oils

- Gear oils.

- Hot Press in plywood Industries

- Gase Power Generation Plant

- Hydro Power Generation Plant

- Thermal Power Generation Plant

- Steel Plant

- Cement & Ceramic Industries0

- Hydraulic Press & Hot / Cold Steel Mills.0

- Bearing Lubrication System.

- Pulp, Cotton, Sugar & Paper Plants.

- Removes coolant, sludge, & chip from the sump tank

- Filters the sludge and chips from the coolant fluid

- Returns filtered coolant to the machine sump tank

- Moves the coolant to waste for disposal

- Eliminate Oil Change.

- Eliminate Mechanical Filters.

- Increase Production And Reduce Rejection.

- Increase Life of pumps, Valves & Seals.

- E H & S (Environment, Health & Safety) friendly.

- Longer Oil Life.

- No Oil Leakages.

- Longer Equipment Life.

- Low Operation and Maintenance Cost.

- Energy Saving by keeping Oil Clean.

- Easy to operate for an efficient method for continuous removal of moisture from oil.

- No damage to oil and the unit offers dry, dehydrated oil.

- Significantly reduced residence time with fast and efficient heat transfer

- Reduced pressure drop

- fouling and ability to process high-viscosity and high-solids materials

- High evaporation ratios.

- Easy to clean/maintain equipment.

S.NO

| Degrees of Cleanliness

| Adopting a Vacuum Dehydration Process

|

1. | 100% | Free and emulsified water alongside free gases |

2. | 95% | of dissolved Water |

3. | 90% | of dissolved gases |

Comparative analysis of Vacuum Dehydration With Centrifugal water removals:

Centrifuging | Vacuum Dehydration |

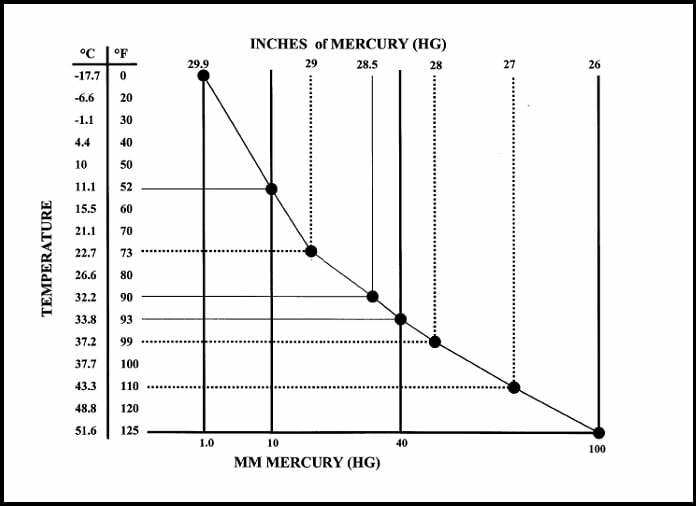

Heating oil to Approximately between 70 to 80°C is required to efficiently extract water | Whereas in LVDH technology, the Water is removed from oil even less than < 55°C. |

Heating oil depletes additives. | No additive depletion. |

Must be used off-line. All related machinery must be stopped to drain oil into barrels / tanks for cleaning. | Can be used on-line, is therefore user-friendly. |

Somewhat cleans low molecular weight oxidized oil fraction | Easily removes low molecular weight oxidized oil fraction |

Cannot remove emulsified water. Gear pumps used in centrifuging increase emulsification. ; | Easy & total removal of free & emulsified water / moisture. |

Cannot remove low molecular weight oxidised oil fraction | Removes |

Cannot remove dissolved gases like Ammonia / Nitrogen. | Removes |

Cannot remove solid impurities below 10 micron, efficiently. | In conjunction with Electrostatic-oil Cleaners, removal efficiency is better than 0.01 micron. |

Centrifugal systems do not clean any dissolved gas | Clears the dissolved gasses very easily |

Many high speed moving parts requiring frequent maintenance | Only two pumps. Vacuum & discharge & slow moving parts. |

| Automatic water discharge. |

Heating oil to Approximately between 70 to 80°C is required to efficiently extract water | Whereas in LVDH technology, the Water is removed from oil even less than < 55°C. |

Depleting anti-oxidation additive | No additive depletion |

Somewhat clears emulsified water | Easy & total removal of free & emulsified water |

Somewhat cleans low molecular weight oxidized oil fraction | Easily removes low molecular weight oxidized oil fraction |

Centrifugal systems do not clean any dissolved gas | Clears the dissolved gasses very easily |

It consumes very High energy | As compared to the centrifugal system it consumes very low energy |

Do you have questions? We have the answers.

Destiny standout as the most reliable supplier manufacturer, exporter of low vacuum dehydration machine, Low Vacuum Dehydration Unit,

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content