Particles whisked along with high flows and pressure result it being driven into tolerences and causing components and valves to stick and malfunction the sandblasting effect of solid contaminants multiplies the presence of particles exponentially

Our Products

- Oil Filtration Machines

- Hydraulic Oil Filtration Systems

- Electrostatic Liquid Cleaning (ELC) Machines

- Elc Collector-25c,50c,100c

- Low Vacuum Dehydration Unit (LVDH)

- Filter Cartridges

- Coolant Sump Cleaner

- By-Pass Filters

- Oil Transfer Unit

- Electrostatic Oil Filtration Machine

- Oil Analysis Equipment

- Contamination Cleaning Kit (CCK)

- Oil Skimmer

- Dedicated Motorised Filtration Unit

- HF series Filtration System-45LPM-54LPM

- Magnetic Oil Filtration Unit

- Highly Effective Filter Media

Applications:

- Plastics Injection Moulding Machines.

- Steel Plant & CNC Machine Tools

- Bearing Lubrication System.

- Hot Press in plywood Industries

- Cement & Ceramics Industries.

- Earth moving, Construction & Mining Equipments.

- Aluminum Extrusion & Die Casting Machines.

- Aviation, Railways & Automobiles.

- Power Transmission Plant

- Power Generation. Gase, Hydro & Thermal

- Hydraulic Press & Hot/Cold Steel Mills.

- Tunnel Boring Machine

- Blow molding

Reasons for critical hydraulic systems to fail :

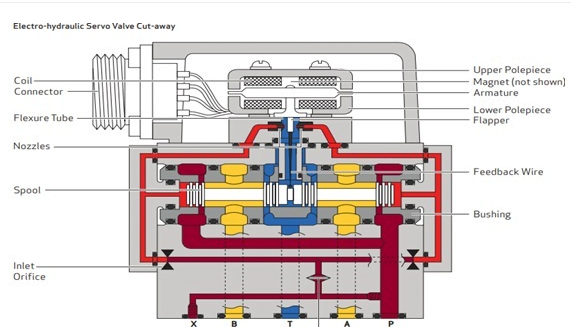

Todays hydraulic systems contain minute pilot circuits with electronically controlled high pressure valves, which produce the exact hydraulic force to move the proportional valve directional spool.The internal parts have low tolerences and right size particles can render the equipment inoperable .

Hence these particles are a must to be removed from the oil.

Control pumps and servo valve malfunction :

- REASONS-1 VALVE JET STEERING – Sticking of large contaminants in the narow passages

- REASON-2 FIRST STAGE STEERING- Wear of ball surface to ovalty due to smaller metal contaminants results in wrong steering of main spool.

- REASON -3 NO OVERLAP IN EDGES OF SERVO VALVE- is restricted by contamainants and results in sticking of valve.

- Control pumps and servo have very critical tolerences 1-10 micron and are very susceptible to fine contaminants.

- NAS 6 ISO CODE 15/12 can be attained by depth filtration to ensure Kleen oil and a long trouble free operation of system.

Wear Particles & Contaminants in Machine Hydraulic Oils: What You Need to Know

Hydraulic oil is the lifeblood of industrial machines. But over time, this vital fluid can get contaminated with microscopic wear particles and other impurities — leading to system inefficiency, downtime, and costly repairs.

Understanding the types of contaminants in hydraulic oil and how they affect your system is critical to maintaining peak performance and reliability.

What Are Wear Particles in Hydraulic Oil?

Wear particles are tiny metal fragments generated from friction between moving parts inside hydraulic systems — such as pumps, valves, cylinders, and motors.

These particles are often invisible to the naked eye but can severely damage components by:

- Accelerating abrasion and erosion

- Blocking small orifices and clearances

- Reducing oil life and increasing temperature

- Causing premature seal and bearing failure