Portable Oil Filtration Machines

BU SERIES

For any hydraulic system, basic operating principle remains an equivalent – generating force through non-compressible fluids

Fluid performs the subsequent four fundamental functions during a portable hydraulic system:

• It generates force and motion because the flow is modified to pressure.

• It resides in a space between different metal surfaces. It creates a seal that will help in eliminating pollutants by providing a pressure barrier.

• It acts as a lubricant for various metal surfaces.

• It cools down system component

It’s imperative to change the filters after a selected number of hours.

Maintains oil quality at least 2 to 5 grades cleaner than new oil.

Reduces machine hydraulic repairs by at least 25% to 35%.

Reduces waste oil disposal volume by 40% to 75%.

Ultrafine filtration (0.1 microns) with water removal capability.

Provides significant economic payback.

Environmental benefits.

SERVICE OIL CLEANING

Typical applications

- For machinery with large volumes of oil.

- Perfect for lube systems and high viscosity systems.

- Successful in cleaning hydraulic testing lines

- Heavy industrial press.

- Die Cast Facilities

- Aluminum Extrusion Facilities

- Injection Molding Facilities

Case studies

Explores few case studies that highlight the positive outcomes achieved by Destiny that have embraced innovative oil filtration systems.

Selecting the appropriate portable hydraulic oil filter (Portable Oil Filtration Machine) cart is extremely important–

It depends on the type of device/system and oil you’ve got. Grades of oil, water-oil emulsions, water-glycol, and artificial hydraulic fluids are fluids commonly used. Oil cleaning has become the need of the hour for all applications with hydraulic or any mineral oil. Amount of oil in machines, cleanliness, standards, tolerances of critical valves, number of machines, etc. help us determine suitable filtration units for fast ROI and cost savings on your investment. Clean oil devoid of contaminants and oil cleaning practices that remove water from oil are needed in the everyday working of industrial machinery.

For any hydraulic system, basic operating principle remains an equivalent – generating force through non-compressible fluids

Fluid performs the subsequent four fundamental functions during a portable hydraulic system:

• It generates force and motion because the flow is modified to pressure.

• It resides in a space between different metal surfaces. It creates a seal that will help in eliminating pollutants by providing a pressure barrier.

• It acts as a lubricant for various metal surfaces.

• It cools down system component

The design of a portable oil filtration machine can vary depending on the specific application and the types of oil being filtered. Some common types of filters that may be included are:

- Coalescing filters, which remove water and other liquids from the oil.

- Absolute filters, which remove particles and other contaminants from the oil.

- Magnetic filters, which remove metal particles and other ferrous contaminants from the oil.

Portable oil filtration machines can be powered by electricity or by compressed air, and may include a variety of features such as digital displays, automatic shut-off valves, and alarms to alert the operator to filter changes or other issues.

Destiny also serves a wide range of other hydraulic machinery:

- Injection and blow molding plastic machines

- Stamping press

- All types and models of hydraulic power packs in paper, printing, steel & iron, car manufacturing and assembling, and petro-chemical industry

- Bending, cutting, punching press

- Rubber press

- Hydraulic systems of harbor, mobile and construction machinery.

- Hydraulic robots

- Test benches

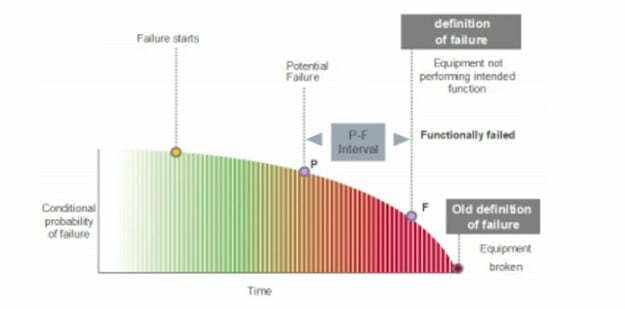

UNEXPECTED HYDRAULIC FAILURES

Pollutants can enter hydraulic systems by various ways:

• During the manufacturing and production process, many contaminants remain within the system like dirt, metal, and rubber particles from seals and hoses, welding slag, debris and rust from machine components, sand from castings, etc.

• While adding the fluid, a number of the pollutants enter the framework one method or another. This occurs because oil isn’t clean and isn’t filtered well before putting it inside the mechanism.

• During normal hours of operation, systems can receive internal pollution as a result of standard wear and tear in some parts. The continuous pump rotation could also be taken as an example.

• Pollutants enter the system externally during normal working hours. They may enter through loose seals, breather caps, and other sorts of openings.

Without any regular maintenance, fluid conditioning & preventive measures, component failure, etc., persisting for an extended time may result in costly downtime. To remove these contaminants, conduct a comprehensive fluid analysis-CALL US FOR FLUID ANALYSIS

Don’t change your oil, filter it!

Can’t find what you’re looking for?

Contact Us for overarching Solutions

Experience our top-notch filtration and oil cleaning solutions designed to meet your specific needs.

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations.For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content