Frequently Asked Questions | Destiny International

Question:

Why Hydraulic Oil Filtration Is Beneficial? Why Should We Invest In Cleaning Oil?

Foreign particles when enter into systems hydraulic fluid cause damage to our hydraulic systems.

Contamination issues disease hydraulic systems and hence decrease efficiency, increase expensive repairs and failure of systems.

Three fourth of hydraulic system failures are traced back to contamination levels in hydraulic fluid.

So, it makes common sense to prevent contaminants to enter into a system and to proactively remove them using measures and systems such as filtration carts, dedicated bypass systems, breathers, inline filters, etc.

TYPES OF CONTAMINANTS

ABRASIVE OR PARTICULATE CONTAMINANT

These include sand, dirt of metal flakes-leading to cavitation, formation of vapors filled cavities and are serious concerns for pump, valve, motor failures. These have a sandblasting effect in the piping and flow systems, further generating more contaminants.

NON-ABRASIVE CONTAMINANT

Elastomeric seals and chemical by-products are equally damaging –clogged parts, stuck valves are failures generated by them. Likelihood of cavitation increase with presence of non-abrasive contaminants.

MOISTURE CONTAMINANT

The increase in oxidation is tenfold with presence of moisture.

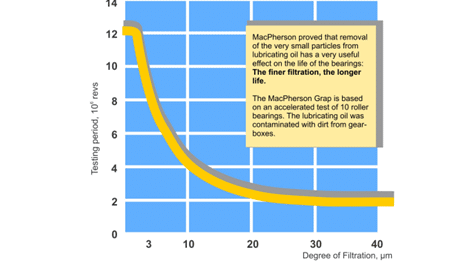

This graph indicates that by increasing filtration ratio from 30 micron to 3 micron component life increase 3-4 times

IDENTIFYING SOURCES OF FLUID CONTAMINATION

The importance to understand the various sources of fluid contamination can help us preventing it.

At the end of the day, contamination can occur almost anywhere. But if you know when and where it’s happening right steps to correct and minimize any contamination can be taken.

- Hydraulic Fluid Manufacturing

- Hydraulic Fluid Production & Storage

- Handling & Transfer

- Operation & Maintenance Of Equipment

BASICS-PREVENTING OIL CONTAMINATION

- Regularly Test & Analyze Hydraulic Fluid

- Remove Particulate Contamination

- Keep Everything Clean

- Properly Store & Handle Hydraulic Fluid

- Filter Fresh Hydraulic Fluid

BENEFITS

Benefits of a hydraulic filtration system-

CONVENIENCE

One of the biggest pros of a hydraulic filtration system is its portability any job site location, this hassle free transportation makes it easy to filter your hydraulic power unit. Designed with ease in mind simply attach the unit to its correct power source, attach compatible hoses, double check the filter and allow the fluid to filter completely through. The process is swift, effective and easy to follow all benefiting your project and products.

EXTENDED LIFE ON POWER UNITS

The ability to keep your machines functioning longer is directly tied to filtered oil . By investing in an hydraulic filtration system you can component life increase drastically. A filtration cart removes any particles from your component’s oil continuously and clean oil favours extended life of power packs .

ADAPTABLE

A major benefit of utilizing a hydraulic filtration system is the adaptability to any hydraulic system ,your machines can stay filtered and productive, oil cleaning is easy using filtration portable carts.

TESTING AND TRACKING OF OIL

Testing the oil within your machines will allow you to determine what contaminants are affecting your machine and therefore guiding you to use the correct filtration system. If you are cleaning oil of your hydraulic equipment regularly you should be testing your oil correctly. By adding this into your planned maintenance you are now able to track patterns, concerns or recognize possible improvements for the use of your machines and its oils and fluids.

OVERALL EFFICIENCY AND PRODUCTIVITY

When tackling a job the main focus is to get it done well and get it done efficiently.

It is a preventative process that will keep your hydraulic and automation systems functioning properly without slowing down when the job gets rough.

Reactive maintenance takes up your valuable time and assets, by interlacing hydraulic oil filtration into your routine and work projects you are being extremely proactive.

Question: What is difference between hydraulic pump and hydraulic motor?

Basically, Hydraulic pump is a device that moves hydraulic fluid with the help of motor typically run by electrical energy. A hydraulic motor is a mechanical actuator that converts hydraulic pressure and flow into torque and angular displacement, rotation.

Question-Why should I change filter element at the right intervals?

The objective to be achieved is to have clean oil at all times till the machine is in operation. Replacing filter media either when choking or clogging indication is reached or if time interval as advised by filtration system manufacture, which can range from 3-12 months will maintain the oil cleanliness level at all times 24x7x365 days. There shall be no window period when the machine is susceptible to wear and tear due contamination presence. This can always be monitored by having routine oil analysis at regular intervals.

Question-What capacity of filtration unit should be installed or purchased by me?

Normally the filtration system manufacturer requests for information regarding the application, machine oil to be filtered, oil grade, oil sump capacity, tolerances of machine parts, cleanliness level required. These help advice most suitable filtration system.

Question-What is clean oil and what does oil cleaning achieve?

Clean oil is quantified for cleanliness parameters as per the specification of the machine manufacturer while determining the fluid of power transmission considering its viscosity, working temperature, etc. Oil cleaning will be required to maintain that parameter to keep the machine in good working condition.

Our Products

Frequently Asked Questions | Destiny International Frequently Asked Questions | Destiny International Frequently Asked Questions | Destiny International ferrocare elc machine

Destiny standout as the most reliable supplier & Manufacturer exporter of Hydraulic oil filtration machine , Hydraulic Off-Line Filtration Units, oil filtration machine in india , Hydraulic Oil Filtration Machine , portable oil filtration systems , LOW VACUUM DEHYDRATION MACHINE , Manufacturer In India, COOLANT SUMP CLEANER MANUFACTURER AND SUPPLIER IN INDIA , portable oil filtration systems

Let's make something great together

Are you ready to save money ? Ask me anything about