PREAMBLE

Hydraulic oil grade in ISO 32,46,68 and other grades are used in Industrial sector and machines.

While working it picks up contaminants in form of dirt,wear particles and water.Contamination particles circulating in fluid system cause defects like abrasion, surface fatigue and erosion.

It reduces system efficiency, accelerates component wear ,reduces performance ,lowers productivity, increases operating cost and may even lead to major breakdowns like damage to seals, pumps, servo valves, cylinders and other components. Hence it is essential to regularly check and test the quality of hydraulic oil used in systems for their efficient working.

PROPERTIES TO BE CHECKED

1) Viscosity@40 deg celcius

2) Water content in ppm

3) Total acid number(tan)

4) Suspended particle count(nas/iso code)

FREQUENCY OF ANALYSIS

Hydraulic oil should be tested every 1000 machine hours

MAXIMUM ADMISSABLE TOLERANCES

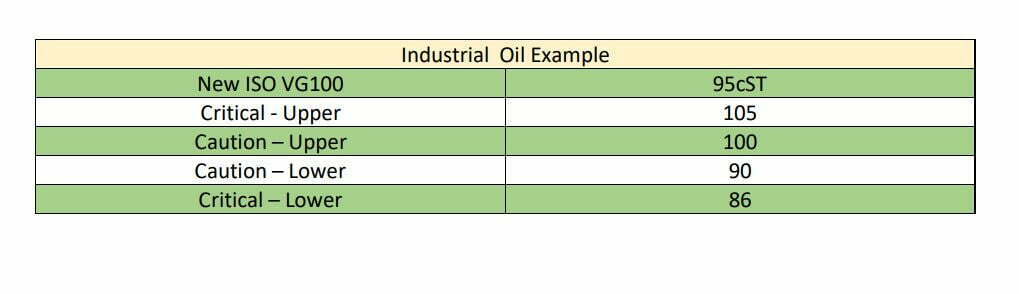

a)Viscosity

- *Twice this amount for oils with VI improvers

- **Crankcase of limits based on cSt @100*c ; industrial oil based on cSt @ 40*c

- Note : Severe Environment oils are at high risk for thermal and oxidative degradation .

WATER CONTENT

Maximum permissible ingress of water in the hydraulic oil is 0.1%(1 ltr of water per 1000ltrs of hydraulic oil)

ACID LEVEL

Fresh oil TAN is up 0.5 mg KOH/gm.The TAN of oil should not exceed 1 mg KOH/gm.If it exceeds ,the oil needs to be changed immediately after cleaning of tank

SUSPENDED PARTICLES

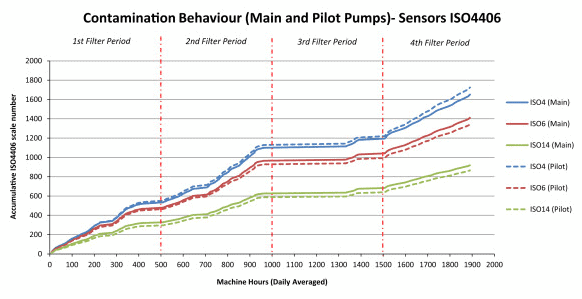

The permitted suspended particles is different for different hydraulic components.

Increase in suspended particles and water content are normally the main cause of damage to the hydraulic components and should be regularly monitored.

If the oil is used for longer periods the viscosity and TAN numbermay exceed limit and should be changed.

S.NO | HYDRAULIC COMPONENT | REQUIRED PURITY ACCORDING TO | |

ISO :4406 | NAS 1638 | ||

1 | SERVO VALVE APPLICATION

| ≤17/14/11 | 5* |

2 | PROPORTIONAL VALVE | ≤18/15/12 | 6* |

3 | VANE PUMP,VANE MOTOR,PISTON PUMP ,RADIAL PISTON PUMP,GEAR PUMP FLOW CONTROL | ≤18/16/14 | 7 |

4 | VALVE,PRESSURE VALVE,CYLINDER | ≤20/17/13 | 8 |

METHODS FOR COLLECTING OIL SAMPLE

Oil sample should be collected from sample points provided by the manufacturer. In case not provided, oil sample should be taken before the return filter.

For 100ml sample -a 200ml glass bottle free from particles and with suitable cap is required.

All samples must be clearly marked for identification/date of collection/oil grade/machine details.

A training procedure is required to learn taking oil samples.

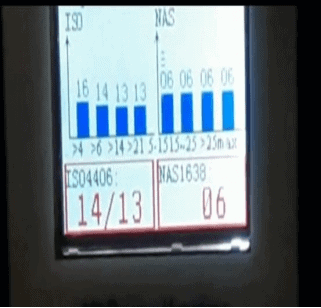

STANDARD FOLLOWED FOR MEASURING SUSPENDED PARTICLES

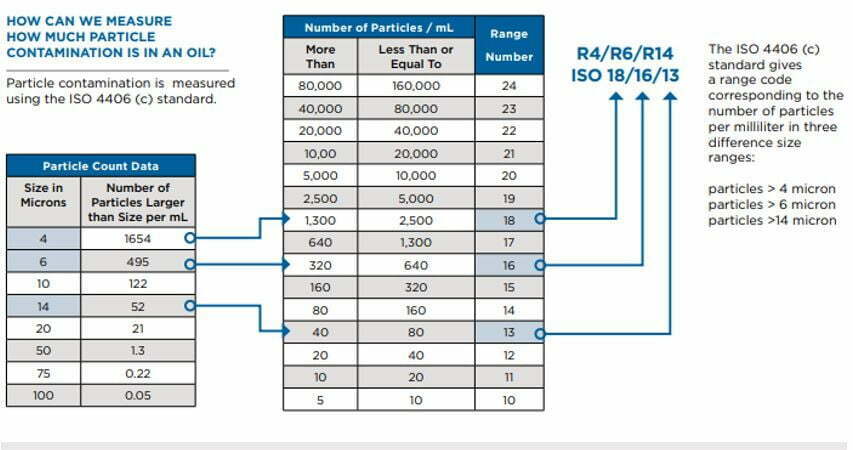

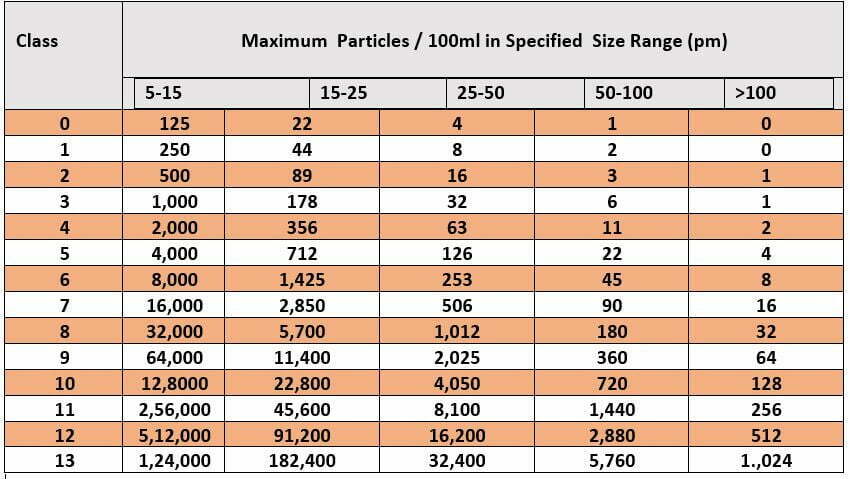

Degree of purity of oil is measured as per ISO 4406:1999 OR NAS VALUE STANDARD.

GRAPHICAL REPRESENTATION OF CONTAMINATION LEVEL WITH MACHINE HOURS

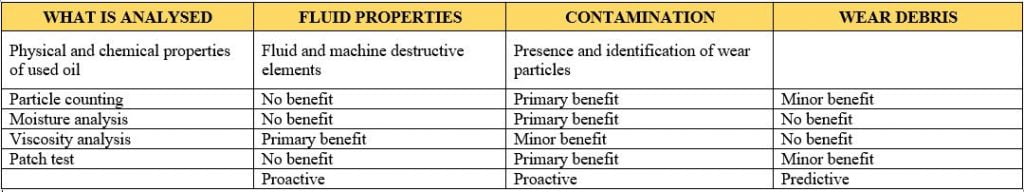

METHODS FOR ANALYSIS OF OIL QUALITY

- Lab test sample.

- Inline measuring instruments.

- Inline measuring instruments are portable and can be installed permanently or temporarily with a pressure line for measuring and monitoring.

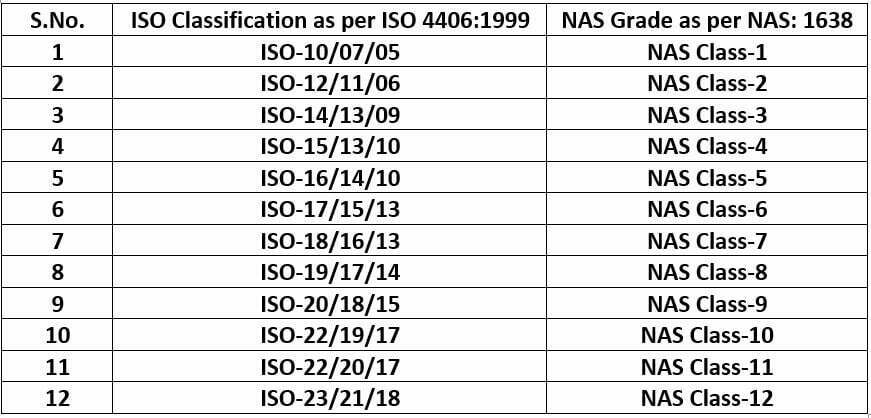

Equivalent Value to other standard classification

SUGGESTION

- Sample test schedule should be followed by enterprises for monitoring particle contamination and moisture content.

- Separate dedicated filtration systems Destiny make should be installed for cleaning hydraulic oil systems.

- Dehydration Low vacuum or cellulose depth filters should be preferred for removal of moisture.

- Desiccant type breathers should be used instead of conventional breathers.

Don’t change your oil, filter it!

Can’t find what you’re looking for?

Contact Us for overarching Solutions

Destiny standout as the most reliable supplier & Manufacturer exporter of Water Glycol Filtration Units, Water Glycol Filtration Systems, Water-Glycol Hydraulic Fluid Filtration systems, Water Glycol Filtration Machine, water glycol filter, Water Glycol Filtration Machine in India, Portable Hydraulic Oil Filtration Unit, Hydraulic oil Filtration Machine

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content