DEDICATED MOTORIZED FILTRATION UNIT

DEDICATED MOTORIZED FILTRATION UNIT

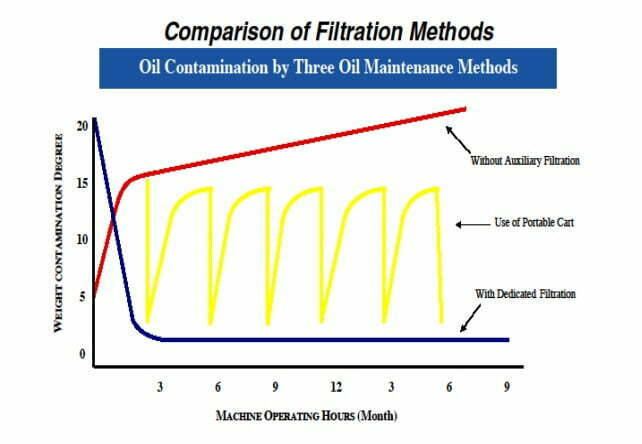

Dedicated motorized filtration equipment is the best choice for improving equipment reliability because the system is continuously on and performing, The most compact and technically perfect filtration unit is EP 200IN and 400IN. We call it the reliable performer.

Motorized filtration unit is a specialized device that uses a motor to power a filter system for removing contaminants from oil. These units are commonly used in a variety of industries, including HVAC, industrial manufacturing, and water treatment.

The use of a motor allows for a more efficient filtration process, as it provides the necessary power to run the filter system. Motorized filtration units can also be designed to handle larger volumes of air or water, making them ideal for use in large commercial or industrial settings.

With dedicated kidney loop filtration system which is motorised and permanently installed on a machine, be assured your current system oil, reliability efforts are spot on. Oil cleaning with dedicated filtration is hustle free and just require routine monitoring to keep clean oil.

We have assisted our customer by installing hundreds of dedicated units on hydraulic power packs and machines.

This tool that has become a must is dedicated filtration system designed to screen the oil 24×7. This system never lets any contaminant in the system at any point of machine life.

All you need is to monitor filter clogging indication or buzzer indication to replace filter in due time and you have ultra clean oil at all times.

MULTI STAGE FILTRATION

Stage 1ST – Suction Wire mesh Washable Filter

Stage 2ND -Magnetic High Strength Filtration

Stage 3RD -Depth Filter (Accuracy -0.1 Micron, Beta Ratio-1.5:750)

| MODEL | EP 200 IN | EP 400 IN | EP 800 IN |

| NUMBER OF DEPTH FILTER | 1 | 2 | 4 |

| ACCURACY (MICRON) | 0.1 | 0.1 | 0.1 |

| OIL HANDLING CAPACITY | UPTO 1200 LTRS | UPTO 2500 LTRS | UPTO 5000 LTRS |

| MAGNETIC FILTER | YES | YES | YES |

| MOISTURE ABSORPTION | YES | YES | YES |

- Extended Oil Life

- Improved Machine Performance,

- Reduction In Breakdown

- Lesser Leakages/Oil Wastage

- Environmental Benefits

Improved air or water quality: The use of a motorized filtration unit can significantly reduce the presence of pollutants, allergens, and other contaminants in the air or water, resulting in a healthier and safer environment.

Increased energy efficiency: Motorized filtration units often use less energy than other types of filtration systems, which can result in lower energy costs and a more sustainable operation.

Greater durability: Motorized filtration units are typically built to last longer than other types of filtration systems, which can result in a lower overall maintenance cost.

Customizable options: Motorized filtration units can be customized to meet the specific needs of different industries and applications, such as HVAC, industrial manufacturing, water treatment, and more.