Abstract

Are we colonizing ourselves again by exporting low value raw materials and importing high value goods? How do we reverse this wheel by contributing to domestic manufacturing? This study shows how a customer changed over to better performing and less expensive Indian filtration system as compared to Danish and equipment made in UK.

DESIRE FOR A SOLUTION : Trial were invited by the case organization from a leading Oil filtration systems manufacturer. Expenses of the trial were borne by the organization to enable purchase of right equipment. Objective was for purchase of 10 nos Filtration systems that could provide cost-effective high performing hydraulic oil filtration machine to be installed on ISGEC sheet cutting press. Parameters of trial and target pricing were established beforehand for determining conclusion of trial results.

LOCATION : Gujrat ,India, Case organization is one of the largest sheet metal key auto systems manufacturing organization in India.

PROBLEM : It was experiencing high purchase cost of capital hydraulic oil filtration machines and spares purchased from manufacturer from Denmark and their distributors in India.

SOLUTION : Destiny International-make Focus portable cart 800 IN was sent for the trial and in a short span of 2 days it was concluded by the end user at its in-house lab the results obtained far surpassed the results from manufacturer for Denmark and UK, whose equipment were under trial since previous 10 days.

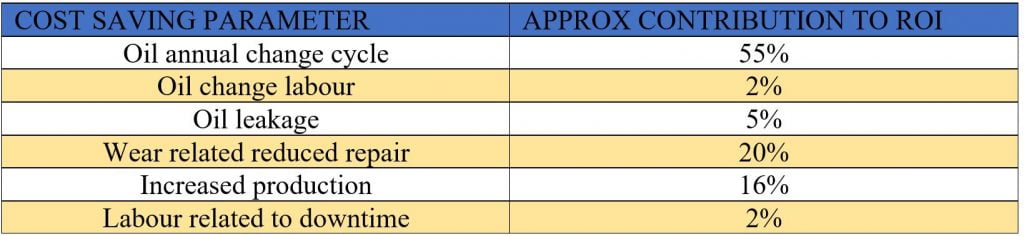

The costing of capital investment was 50 % less and spares were 100% lower in pricing ROI<1 YEAR

BEFORE FILTRATION ISO 20/19/17 DIRTY OIL

AFTER ONE PASS 18/16/14 PROCESS -OIL CLEANING

AFTER ONE PASS 18/16/14 PROCESCLEAN OILS -OIL CLEANING 14/12/11

Oil Filtration Systems hydraulic oil filtration machine SDFC1888KF85 SDC1888

CONCLUSION: A nationalistic proactive approach by end user and a fresh mind set to promote domestic engineering leading to enhanced national security and national revenue and improved customer protection and savings after using our Oil Filtration System.

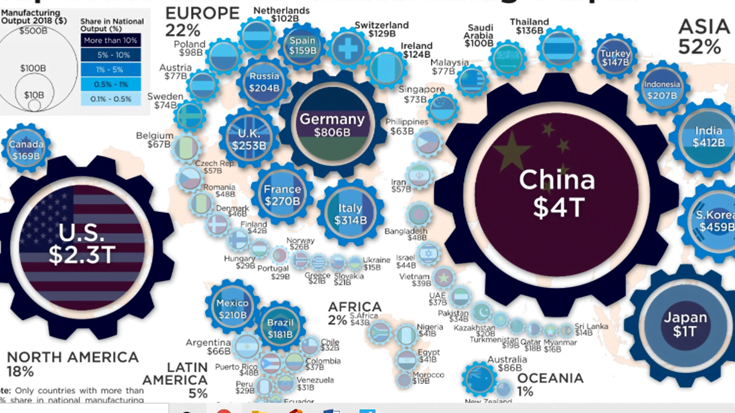

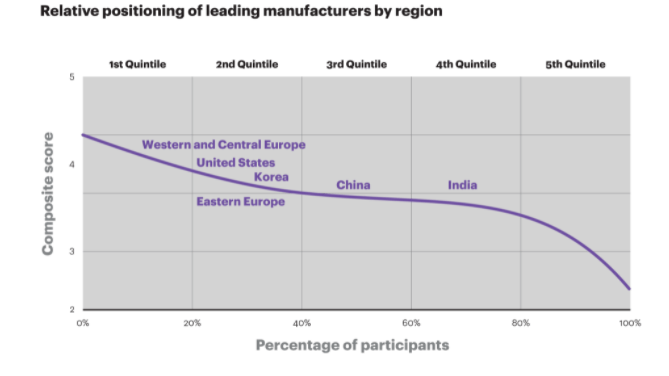

India in the fourth quantile lags behind others, but Indian manufacturers fare better than global averages for cost control because of lower wages and focus on reducing costs, Indian manufacturers face more quality and fulfillment delays. The pace of innovation is slower since we require twice or thrice longer to launch new products and our agility is reduced to scale up or down.

International Brands: (Imported In India)

- Triple -RRR (Japan) , M-Series, E- Series, E-Series and more…

- CJC – Denmark , A-Filters Inserts, B- Filters Inserts and more…

- SDC1888 , SDFC1888KF85 , Water glycol filter SDPC 2088 and more..

MADE IN INDIA

- Destiny International – India , 200HE , 100 Series , 50 Series , 30 Series and equivalents (Manufacturer and Expoter)

Clean Oil

Healthy Machine

A hydraulic oil cleaning machine is a device used to purify hydraulic fluid in hydraulic systems. It removes contaminants such as dirt, debris, and water to maintain the fluid’s quality and protect the system from damage. The machine typically uses filters, centrifugation or other filtration techniques to achieve the desired level of cleanliness

Offline filtration: In this method, the oil is circulated through a filter unit that is separate from the hydraulic system. The filtered oil is then returned to the system.

In-line filtration: In this method, the oil is filtered as it flows through the system. This can be done with a filter element installed directly in the oil circuit or with a filter cart that is connected to the system.

Suction filtration: This method uses a filter element installed in the suction line of the pump to remove contaminants before they enter the system.

Return line filtration: This method uses a filter element installed in the return line of the system to remove contaminants before they re-enter the oil tank.

Don’t change your oil, filter it!

Can’t find what you’re looking for?

Contact Us for overarching Solutions

Destiny standout as the most reliable supplier & Manufacturer exporter of Hydraulic oil filtration machine, Hydraulic Off-Line Filtration Units, oil filtration machine in India, Hydraulic Oil Filtration Machine, Hydraulic Oil Cleaning System, Hydraulic Oil Cleaning System, Hydraulic Oil Cleaning, Hydraulic Oil Maintenance System,Oil filtration systems manufacturer

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content