HYDRAULIC OIL WITH WATER (RELATED MACHINE PROBLEMS AND SOLUTIONS)

Water Contamination ,Oil filtration practices in industries have gained importance over time with assured component longevity. It has been well documented that improvement in particle contamination by one ISO cleanliness code can increase the life of hydraulic valves , pumps and related components by up to 30%.

Now, water in some industries is overlooked as the primary cause of failures. Water is far more dangerous than solid contaminants.

Indian Industry spends lakhs of Rupees to improve cleanliness level and this definitely helps reduce up to 90 % of failures related to oil.

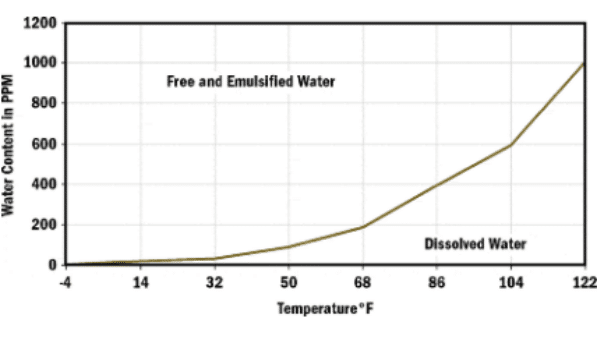

Dissolved water exists as individual molecules in oil-most hydraulic oils that can hold 0.02-0.06% (200 -600 ppm)of water in a dissolved state.

Emulsified water exists after oil is saturated in form of microscopic droplets causing it to become hazy.

In a free state, water has crossed the emulsified state and exists as free water and /or with emulsified water. This free layer normally exists at bottom of the tank.

WATER AND OIL ARE PROBLEMS

- Direct harms include-

- Effect on components

- Aging of oil

- Multifold increase in oxidation

- Destruction in base oil and formation of acids

Washing away of additives

Sludge formation and sediment settlement

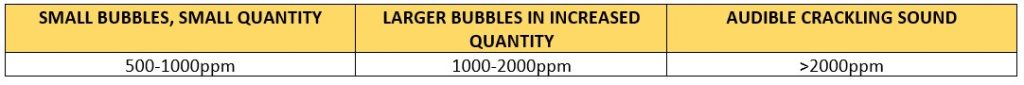

THE CRACKLE TEST (sensitive to free and emulsified water)

- A hot plate 130 Degrees approx. is held and few drops are placed on it.

- Small bubbles-500-1000ppm

- Significantly more bubbles, Slightly larger-1000-2000ppm

- Audible Crackling sound-greater than 2000ppm

- Crackle test ROUGH estimation (easy and fast-negligible apparatus cost

- Water Presence In Oil

Laboratory analysis

The precise method for checking the amount of emulsified, free and dissolved water in any oil is the Karl Fischer test-If used correctly, this test is capable of measuring water levels as low as 10 ppm or 0.001 percent and should be used when more exact water concentrations need to be determined.

EASY SOLUTIONS

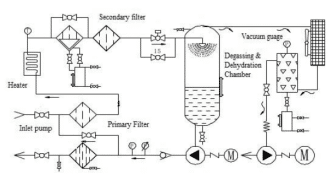

Oil dehydration machines are the simplest means to save your water contaminated oil-with all its properties in place.

ROI on these units is almost immediate if you have a sufficient quantity of water-contaminated oil.

A low vacuum dehydration unit is a semi-automatic unit, which operates by removing water at low temperature and high vacuum conditions.

For routine moisture settling in tanks due to temperature changes and breathing of hydraulic tanks can be handled by installing-DESICCANT BREATHERS.

Desiccant breathers remove contaminants such as dirt and moisture from air entering machinery, sumps, and reservoirs. These are the first barriers and a good breather shall act as a soldier to prevent dirt and moisture to enter the tanks.

Oil cleaning using cellulose media filters –with the property to absorb moisture in oil –whether installed as a BYPASS unit or in portable or dedicated filtration carts are one of the smartest ways to get rid of moisture in oil, without even bothering to raise the temperature and use vacuum dehydration. The capillaries in cellulose fiber act as the smallest filter media holding water molecules in their tubes.

With one of these installed you can get rid of moisture and contaminant in one go and are most preferred

Solutions used by OEM manufacturers of molding machines, diecasting machines, hydraulic presses, or any hydraulic power pack manufacturer. These are considered silent soldiers and performers.

Water Contamination Water can damage oil properties and reduce life of hydraulic machinery by alarming 50%. Due to low tolerance in modern machinery, the continuous pressure vacuum conditions cause the moisture to expand and explode on the walls of metal surface, causing wear and continuous blasting of inner surfaces with particles and vacuum explosions.

Don’t change your oil, filter it!

Can’t find what you’re looking for?

Contact Us for overarching Solutions

Destiny standout as the most reliable supplier of Hydraulic / Fluid Reclamation Services & Water Contamination in Hydraulic and Lube Systems, Contamination in Hydraulic Systems, Water contamination in hydraulic oil, Water In Oil Contamination

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content