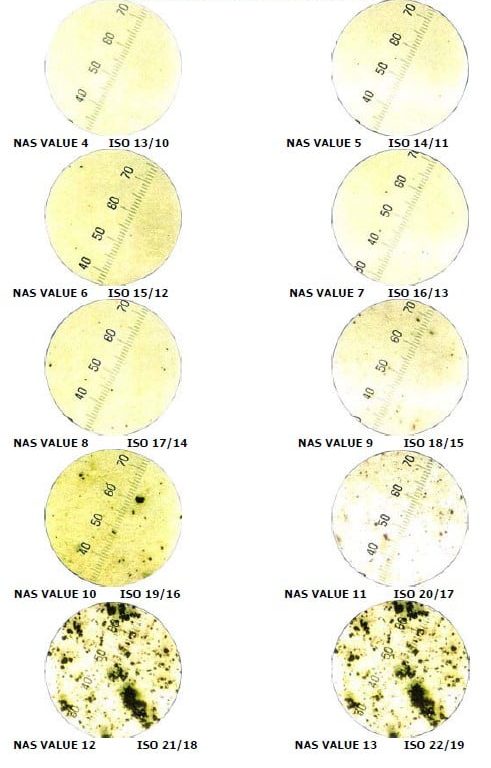

Nas Value 4406 / ISO Code Patch Comparison Chart / Nas Value Comparison Chart

Nas Value 4406 / ISO Code Patch Comparison Chart / Nas Value Comparison Chart

NAS (National Aerospace Standard) is a widely adopted standard to measure the contamination degree of hydraulic oil.

Good quality hydraulic oil is essential in any hydraulic circuit. A key parameter in determining the quality of your hydraulic oil is its cleanliness, or as it is sometimes refered to, the oil’s particle count.

Hydraulic fluid is used as the motive power for many actuated valves, often in subsea applications. Integral to the actuator are components with small bores that can become blocked if the fluid has particles of debris within it. Clearing a blockage can be difficult, time consuming and very expensive, especially in subsea applications. Therefore it is common to specify that the hydraulic fluid used in the system is cleaned to a measurable degree of cleanliness e.g. NAS 6.

Measuring hydraulic cleanliness is not straight forward, consequently various standards exist on this subject. The two most likely to be encountered in the oil & gas, and process industries are The ISO Cleanliness Code (ISO 4406), and The NAS 1638 cleanliness standard.

An introduction to each of these allowable particle contamination standards is provided below.

As a minimum an oil analysis should include:

- Particle count (ISO 4406 or NAS 1638)

- Water content in ppm

- Viscosity

- Acidity level (TAN)

- Spectral Analysis (wear metals and additive package).

- 0,8 micron Millipore filter membrane for Sludge detection.

Maximum Values:

the 1st rule is that the oil cleanliness should always be adjusted to the cleanliness requirements of the most sensitive component of the system. For example, if the hydraulic system is using servo-vales, a NAS class 6 or better is of upmost importance. In general hydraulic systems should never exceed a NAS 7 class.

water content is expressed in PPM (parts per million). 1 PPM = 0,0001%. As a rule of thumb water concentration should not exceed 300 PPM.

the viscosity is expressed in cSt. For hydraulic oil typical oil viscosity are 32 cSt, 46 cSt and 68 cSt mg/KOH gr. For lube oil typical oil viscosity are 220 cSt and 320 cSt. The oil viscosity may vary within a range of 25% up or down the initial viscosity. Meaning that a 46 cSt oil will still be within an acceptable range if the measured viscosity is between 33 and 59 cSt

Total Acid Number (TAN): the acidity level or TAN is expressed in mg/KOH gr. Every oil has a maximum TAN value. Ask your oil supplier about your oil maximum TAN level. Typically for hydraulic the maximum level is 1,0 mg/KOH gr. New fresh oil will start around 0,2 mg/KOH gr.

measures the wear metals and the additive package. BUT, note that a spectral analysis is not a substitute for a Particle Count. Typically a spectral analysis is measuring elements with a size below 3 micron, solids but also liquid or chemical compositions! Important is to have the possibility to compare multiple spectral analysis, and to check about the trend. Are the wear metals increasing significantly? Are the additives vanishing?

Don’t change your oil, filter it!

Can’t find what you’re looking for?

Contact Us for overarching Solutions

Experience our top-notch filtration Ultra-fine Oil Filtration Machine to collect all types and sizes of contaminants. It remove all types of particles such as wood, plastic, paper,metal wear, and rubber.

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content