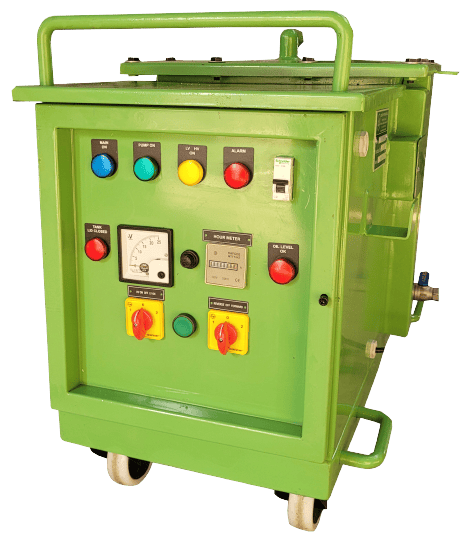

Electrostatic Oil Filtration Machine (ELC25, ELC50, ELC100)

ELC machine are used for super cleaning of oil to NAS 1638 grade level. Efficiency of this machine to super clean the oil will be in the range of NAS 6-7. These machines are available with or without dehydration attachment. They work on high voltage laminar flow principle, catchhold magnetic/non-magnetic ferrous/non-ferrous material.

Overall, an electrostatic oil filtration machine is an effective solution for removing contaminants from oil. It is widely used in a variety of industries and is relatively low maintenance. It can be useful in various applications and can help to extend the life of equipment and improve their performance.

WORKING PRINCIPLE OF ELECTROSTATIC MACHINE

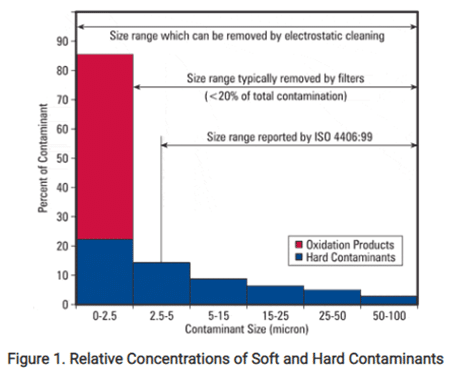

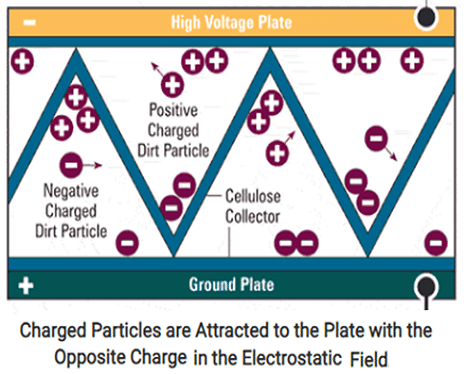

Particle contaminants are charged in an electric field due to contact potential differences with liquid oil. Particles are drawn towards opposite poles and neutral contaminants are collected at the edge of the dielectric media collector filter by gradient force.

Collectors are corrugated dielectric media which once inserted between plate electrodes, electric field deforms, and die electric polarization happens at the tips of corrugated media. The electric field becomes strongest at the tips of collector media and particles are drawn and deposited on the opposite sides –poles and removed.

Smaller particles have greater charge density and are trapped faster and easier to remove.

OIL CONDITION FOR ELC MACHINE

- Temp: Upto 60 C

- Viscosity: below 320 CST Max

- Water content below 500 PPM

- Mineral base oil

-zig-zag pleated- cured and cut to size for various model of ELC of any make

-Suitable for Dust Collector (Di-electric media) any make ELC Machine

- Plastics Injection Moulding Machines.

- Hot Press in plywood Industries.

- Aluminum Extrusion & Die Casting Machines.

- Power Generation. Gase, Hydro & Thermal

- Lubricating oil filtration

- Gear oil filtration

- Steel Plant & CNC Machine Tools.

- Cement & Ceramics Industries.

- Aviation, Railways & Automobiles.

- Hydraulic Press & Hot/Cold Steel Mills.

- Hydraulic oil filtration

- Turbine oil filtration

- No oil changes

- Reduction of hydraulic and lubrication system malfunction, leading to reduced maintenance costs

- Zero downtime

- Reduced oil leakages, leading to clean oil and safe work space and environment

- Better quality control – from consistent pressures in Hydraulic circuit

- Plastics Injection Molding Machines

- Hot Press in plywood Industries

- Aluminum Extrusion & Die Casting Machines

- Power Generation. Gas, Hydro & Thermal

- Steel Plant & CNC Machine Tools

- Cement & Ceramics Industries.

- Aviation, Railways & Automobiles

- Hydraulic Press & Hot/Cold Steel Mills

- Bearing Lubrication System

- Earth moving, Construction & Mining Equipment

- Power Transmission Plant.

- Eliminate Oil Change

- Eliminate Mechanical Filters

- Increase Production and Reduce rejection

- Increase Life of pumps, Valves & Seals

- E H & S (Environment, Health & Safety) friendly

- Longer Oil Life

- No Oil Leakages.

- Longer equipment Life

- Low Operation and Maintenance Cost

- Energy Saving by keeping Oil Clean

- Low Maintenance

Don’t change your oil, filter it!

Destiny standout as the most reliable supplier & Manufacturer, exporter of Electrostatic Oil Filtration Machine, Electrostatic Liquid Cleaning Machine, Electrostatic Liquid Cleaner, Electrostatic Oil Cleaning System,Electrostatic Liquid Cleaning Machines

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content

We respond quickly to emergency outages and situations – call us at (783) 878-1100