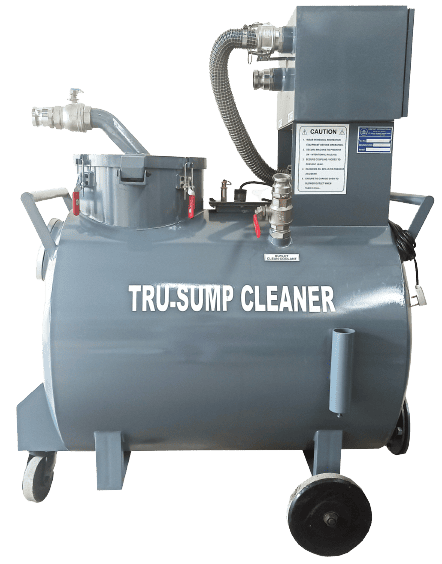

COOLANT SUMP CLEANER

Coolant Sump Cleaner

Sump cleaner is a specialised tool for cleaning the coolant Sump Tank. In just a few minutes a Sump cleaner picks up all fluid and contaminant the filter seperates the soilds from the fluid filtered coolant is returned to the machine Sump Tank.

OBSERVATIONS / CONCLUSION

Saving in Coolant purchase

Reduced Labour

Lesser Downtime

Easy Operation

No shutdown of machine required

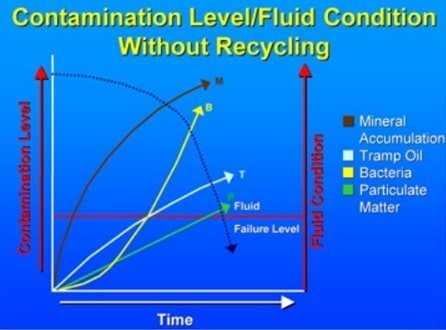

No Fowl smell / Bacterial growth

Environmental benefits

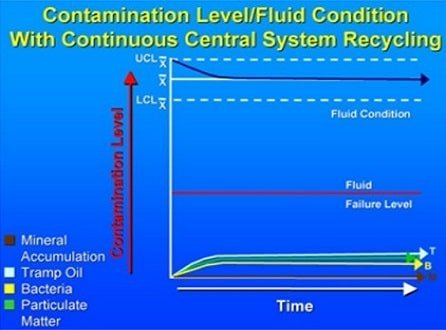

Improved Tool Life: Coolant filtration systems help to remove contaminants from the coolant, preventing them from entering the tool and causing premature wear and damage.

This can help to extend the life of the tool and reduce the need for frequent replacements.

Destiny’s Coolant Sump Cleaner are highly effective in filtering out contaminants from the coolant, including metal shavings, dirt, and other debris that can clog up the system and cause damage to the machine.

The filter media used in a band filter is typically a tightly woven mesh that captures even the smallest particles, ensuring that the coolant remains clean and free of contaminants.

Enhanced Surface Finish: Contaminants in the coolant can also cause scratches and blemishes on the surface of the workpiece.

By removing these contaminants, coolant filtration systems can help to improve the surface finish of the finished product.

This means that the CNC machine can run for longer periods without interruptions, which can improve productivity and reduce downtime.

Increased Efficiency: Clean coolant can transfer heat more effectively than contaminated coolant, allowing the machine tool to operate at higher speeds and with greater efficiency.

This can help to reduce cycle times and increase productivity.

Reduced Maintenance Costs: Contaminants in the coolant can cause damage to the machine tool and other components of the system.

By removing these contaminants, coolant filtration systems can help to reduce maintenance costs and downtime associated with repairs.

Improved Environmental Sustainability: Properly filtered coolant can be reused, reducing waste and promoting environmental sustainability.

A machine tool coolant filtration system is an important investment for any metalworking operation.

It helps to protect the machine tool, improve the quality of finished products, and promote more efficient and sustainable operations.

WORKING PRINCIPLE OF ELECTROSTATIC MACHINE

Destiny International Sump Cleaner removes sludge, metal chips & swarf from Coolant / Oil tanks & filters it via reusable steel mesh filter. The System Works on the Principle of Vacuum Suction. A powerful vacuum blower creates vacuum in the tank of the unit, which sucks in coolant, metal chips Swarf etc, passing it thru mesh basket. Contamination gets collected in the basket & clean coolant flows through to the tank of the unit. A centrifugal delivery pump delivers back the clean coolant.

- Soluble Cutting Oil

- Neat Cutting Oil

- Water Emulsion

- Quenching Oil

- CNC Machines

- Storage Tank

- Grinding

- VMC

- Hobbing

Removes coolant, sludge, & chip from the sump tank

Filters the sludge and chips from the coolant fluid

Returns filtered coolant to the machine sump tank

Moves the coolant to waste for disposal

No Filter Element

No Replacement Cost

Improved Product Finish

Reduced Oil Consumption

Extended Oil Change Period

Reduced Machine Downtime

Reduced Pollution & Environmental Impact

Reduced Storage & Disposal Cost of Waste Oil

• Less power consumption – Uses a single-phase vacuum pump

• Offline coolant filtration system – for multiple cycles of filtration

• Portable and safe – the unit is on wheels, curbing chances of injury

• Faster cleaning process due to vacuum suction

• Robust construction

• Antibacterial residual filtering system

• Improves quality of coolant and ultimately products being machined

• Filters upto 10 microns particle size

• Cleaning process in very short time. E.g.: 10 to 15 minutes for base model

ONE TIME INSTALLATION, LIFELONG SAVINGS

Destiny standout as the most reliable supplier & Manufacturer, exporter of Coolant sump cleaner, Coolant Cleaning Systems, Coolant Sump Cleaning Systems, CNC machine coolant sump cleaning, Industrial Sump Cleaners

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content

We respond quickly to emergency outages and situations – call us at (783) 878-1100