Hydraulic oil filtration machine / Oil filtration machine in India / Oil Cleaning System / Oil filtration systems manufacturer

Ultra Fine Hydraulic Oil Filtration For Critical Machines Applications

Improper maintenance, contaminated hydraulic oil is one of the principal causes of faults in any hydraulic operated machines. In 70% to 90% of cases, damage to hydraulic components is directly attributable to contamination in the hydraulic system. The goal of oil management is to prevent contamination of this kind in order to enhance the availability, reliability and efficiency of ipower packs and machines. Oil management is not strictly the responsibility of the end user, it also involves the manufacturer of the molding machine.

Hydraulic oils can become contaminated through air, water or solid particles. Contamination by solid matter is the primary cause of significant surface damage to hydraulic components through wear mechanisms such as abrasion. The consequences are control inaccuracies, leaks, losses in efficiency, and a shorter service life of parts. As more particles accumulate in the hydraulic oil, wear is further increased. Coarse filter systems are limited in their ability to interrupt this chain reaction of wear.

Our Products

- Oil Filtration Machines

- Hydraulic Oil Filtration Systems

- Electrostatic Liquid Cleaning (ELC) Machines

- Elc Collector-25c,50c,100c

- Low Vacuum Dehydration Unit (LVDH)

- Filter Cartridges

- Coolant Sump Cleaner

- By-Pass Filters

- Oil Transfer Unit

- Electrostatic Oil Filtration Machine

- Oil Analysis Equipment

- Contamination Cleaning Kit (CCK)

- Oil Skimmer

- Dedicated Motorised Filtration Unit

- HF series Filtration System-45LPM-54LPM

- Magnetic Oil Filtration Unit

- Highly Effective Filter Media

Applications:

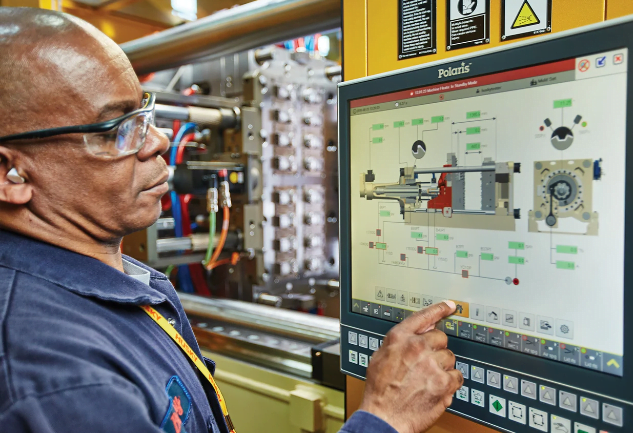

- Plastics Injection Moulding Machines.

- Steel Plant & CNC Machine Tools

- Bearing Lubrication System.

- Hot Press in plywood Industries

- Cement & Ceramics Industries.

- Earth moving, Construction & Mining Equipments.

- Aluminum Extrusion & Die Casting Machines.

- Aviation, Railways & Automobiles.

- Power Transmission Plant

- Power Generation. Gase, Hydro & Thermal

- Hydraulic Press & Hot/Cold Steel Mills.

- Tunnel Boring Machine

- Blow molding

Some Critical Machine Requiring Ultra-clean Oils Moulding Machines :

SERVO VALVES APPLICATIONS :

MTS TESTING RIGS, R & D MACHINES, WIND TURBINES :

MTS TESTING R&D MACHINE

WIND TURBINES

MTS TESTING R&D MACHINE

FOCUS 800IN

PROBLEMS :

- High spares cost.

- Production losses

- Breakdown losses

- High Labour costs

SOLUTIONS :

Ultrafine filtration using depth cellulose wood pulp paper filters. That absorb even the finer contaminants and even routine moisture. Tolerance breach of critical parts is prevented, saving Hugh losses.

Recommended-Dedicated motorized filtration units BU-200/400/800/1200 unit as per oil quantity and contamination levels.

Hydraulic Oil dehydration services

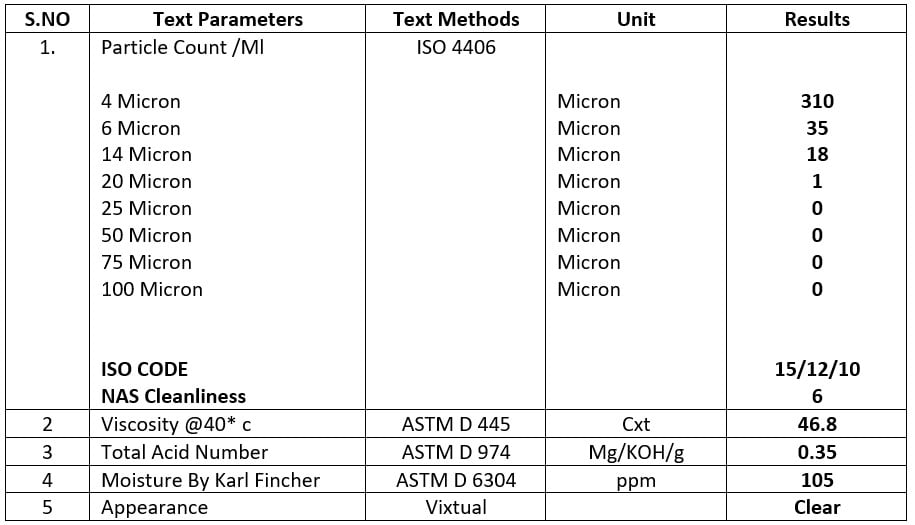

Received Date : 06.09.2022Report Date : 07.09.2022

OIL ANALYSIS -ISO 15/12/10 NAS 6-USING DEDICATED MOTORISED ULTRAFINE FILTRATION UNITS