Oil Filtration Machine | Oil Filtration System

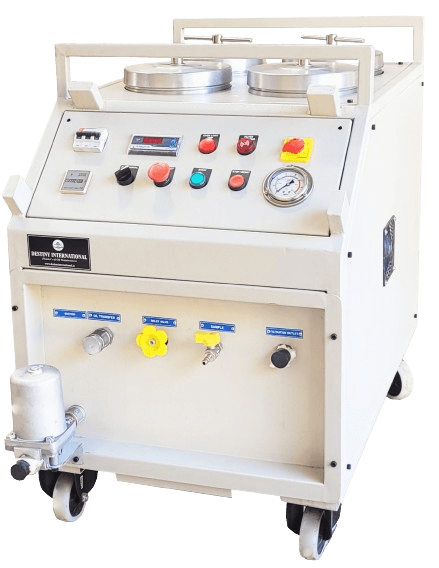

Destiny’s® FD/FP Series Oil Filtration Systems are high end technology machines popularly used for Ultra-Fine Stage Filtration (fine solid particle removal) of lubricating and hydraulic oils.

Discover our high-quality products designed to meet your specific needs

Our range includes advanced filtration systems, cutting-edge oil cleaning solutions, and reliable maintenance equipment.

Each product is meticulously engineered to deliver superior performance, ensuring optimal efficiency and cost-effectiveness for your operations.

Our Oil Filtration Machine is a multi-purpose fluid cleaning machine that can clean most oils such as hydraulic oil, gear oil and many soluble oils and fluids. More than 85% of hydraulic oil failures are caused by contaminants in the oil.

Meeting Our Hydraulic Systems’ High Oil Purification Standards

Our Products

- Oil Filtration Machines

- Hydraulic Oil Filtration Systems

- Electrostatic Liquid Cleaning (ELC) Machines

- Elc Collector-25c,50c,100c

- Low Vacuum Dehydration Unit (LVDH)

- Filter Cartridges

- Coolant Sump Cleaner

- By-Pass Filters

- Oil Transfer Unit

- Electrostatic Oil Filtration Machine

- Oil Analysis Equipment

- Contamination Cleaning Kit (CCK)

- Oil Skimmer

- Dedicated Motorised Filtration Unit

- HF series Filtration System-45LPM-54LPM

- Magnetic Oil Filtration Unit

- Highly Effective Filter Media

Applications:

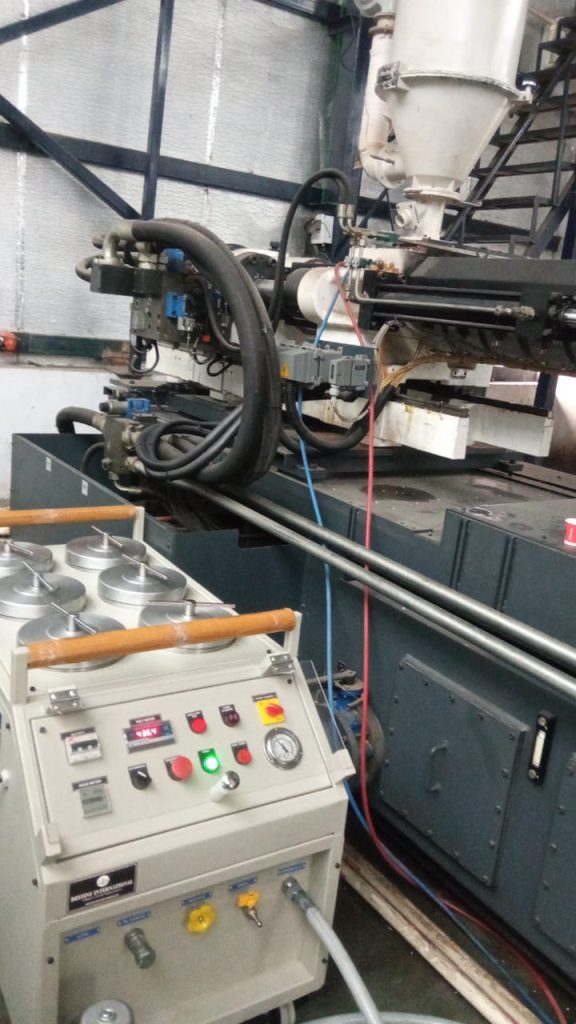

- Plastics Injection Moulding Machines.

- Steel Plant & CNC Machine Tools

- Bearing Lubrication System.

- Hot Press in plywood Industries

- Cement & Ceramics Industries.

- Earth moving, Construction & Mining Equipments.

- Aluminum Extrusion & Die Casting Machines.

- Aviation, Railways & Automobiles.

- Power Transmission Plant

- Power Generation. Gase, Hydro & Thermal

- Hydraulic Press & Hot/Cold Steel Mills.

- Tunnel Boring Machine

- Blow molding

Salient Features:

- Continuous and quick oil filtration.

- Ultra-fine contamination control to finer than 0.1micron.

- Removes contaminant particles down to less than 0.1 microns.

- Reduces the incidence of sticking & worn value components.

- Quickly & Easily Filter cartridge can be changed .

- No machine downtime as oil is cleaned continuously while the machine is in operation.

Why Oil Filtration ?

- Removes Dirt And Contaminant

- Preventive Maintenance

- Optimized Performance

- Enhanced Efficiency

- Reliability and Consistency

- Reduced Maintenance Costs

- Eliminates Water

Features :

- Destiny’s Filtration System maintains the lube oil including hydraulic and lubricants oils at NAS 6 or better.

- Removes contaminations down to less than 1 Micron

- Maintains the rate of contamination removal higher than it is getting generated and is applicable to various viscosity grades upto 680 CST in different applications.

- Prevents contamination related failures of bearing and servo valves.

- Destiny’s filtration system helps Extends oil life and maintained all oil properties.

- Its retards regeneration of continuous wears and hence improves machine Reliability and Productivity.

- Destiny’s Filtration System can also be used for recycling oil used in flushing applications.

Destiny's Oil Filtration Systems (Models) :

Destiny's Oil Filtration Systems Installation:

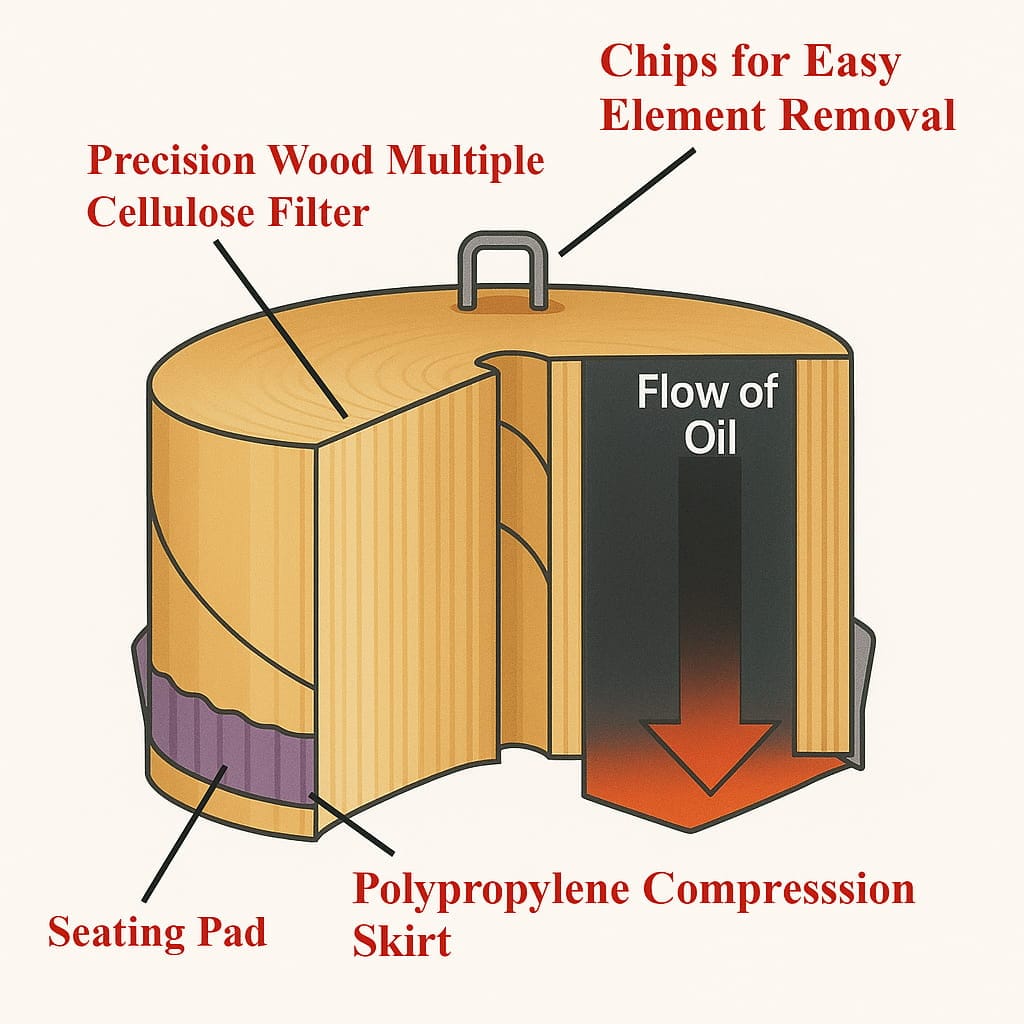

Destiny’s® Filtration Stages

1st stage

Big particles are retained on the top of the filter

2nd stage

Small particles are trapped in the mid stage of the filter element

3rd stage

The smallest particles are trapped in the lower and compressed part of the filter

A revolutionary 3-in-1 element design allows to guarantee absolute filtration effectiveness.

The filter design forces the oil to flow through filter media and creates 3 distinct stages of filtration. The lower part is compressed by a base paper, creating an even finer filter medium.

The filter becomes an excellent diagnostic tool as big PARTICLES are retained on top.

The cellulose filter media absorbs WATER drops and therefore dries the oil to less than 100 ppm.

The industry’s thickest filter, results in the unique ability to absorb and remove oil oxidation residues, well known as VARNISH, or sludge deposits.

Installation Scheme

- Trolley Mounted

- Portable Machine

Benefits

- Filtration Capacity

- Oil Viscosity handled

- Oil Types handled

- Prevents oil oxidation

- Ensures Higher Oil Life

- Prevents Valve Failures

- Prevent Pump Failures

- Increases bearing life

- NAS Cleanliness Class

- 0–680 cSt . For higher viscosities customized model to be ordered

- Hydraulic, Lube, Turbine Oil, Gear Oil.

- By removal of solid particles in oil

- By retaining Viscosity, TBN, Flash Po int, Additive level etc.

- Due to removal of sticky sludge

- Due to removal of micron particles

- Due to moisture & sludge free oil.

Working

Online / Offline. Fitted externally to oil reservoir as a by-pass oil purification system

Oil Drive Systems

- Pump : 20 LPM / 40 LPM / 60 LPM / 80 LPM / 150 LPM / 200 LPM

- Motor: 415 V, 3 Phase, 1500 RPM (standard). Other options & flameproof options on request

Hose Pipes

- Suction Pipe : 3 m hydraulic hose pipe

- Delivery Pipe : 3 m hydraulic hose pipe

Fabrication Structure

- MS (powder coated)

- Castor Wheels with swivel

Filtration Principle

Stage Filtration of reducing microns Filters: The filters used in this skid are made of inorganic fiber glass impregnated media in pleated form for better filtration area. The choice of filter rating and size is done to ensure best filter life, efficiency and performance.

Don’t change your oil, filter it!