Case Study

Oil Filtration

Location: North India

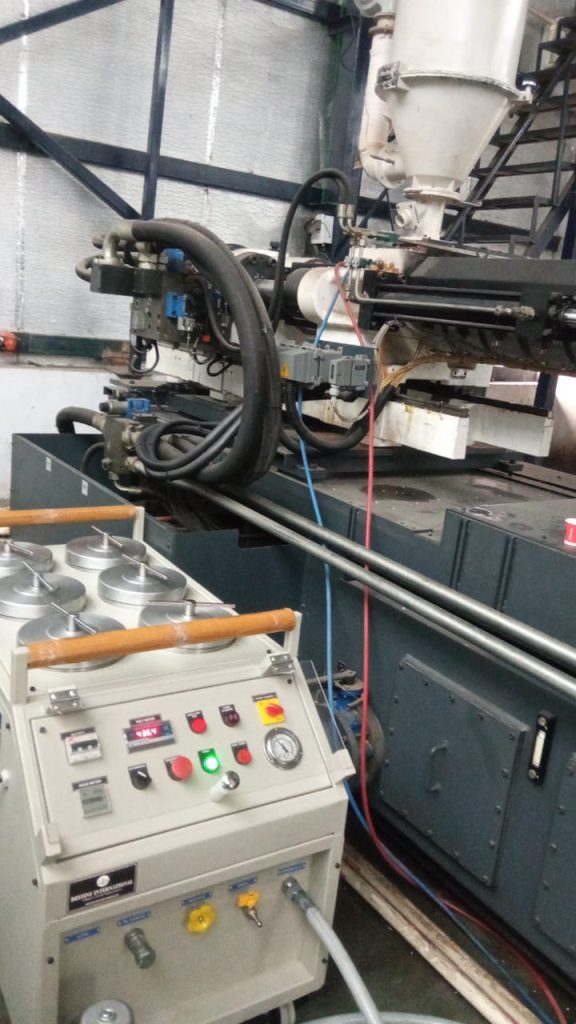

Product Installed: Portable Oil Filtration Machine- BU-400IN

Application Background

Roi- 8 Months-Hydraulic Oil Filtration Machine A Cardboard Compacting Company –Horizontal Bailer, With Multiple Plants location North India

Synopsis

The manufacturer was purchasing 1000 Ltrs of Hydraulic oil Grade 68, every 8 months for replacing heavily contaminated oil in the hydraulic sump tank for each machine. The manufacturer contacted us for resolution and rescue from existing recurring purchases.

A suitable filtration unit was suggested by us and the results of the portable machine Focus 400 IN led to an ROI of fewer than 8 months for the customer.

Synopsis

- Extended oil life.

- Almost zero downtime.

- Reduced labour cost.

- Lower carbon footprints and hence

- environmental benefits.

Problem

- Machine breakdown and valve failures.

- Leakages from seals.

- Investment in purchases for oil every 6 months.

- Pump malfunctions and repair costs

- Due to the inherent nature of business lot of dust was present

Solution

- A dedicated filtration unit focus 400in was installed in closed-loop.

- Ultra fine cellulose media removed contaminants with an accuracy of 0.1 micron and routine moisture.

- Our technician trained the staff for simple push-button operation and audible alarm and clogging indication.

- The Customer Has Got Installed 3 Nos Equipment In Plant -1, For Other Plants Commissioning At Priority

Oil filtration refers to the process of removing impurities from oil, typically through the use of a filter. This can include removing particles such as dirt and metal shavings, as well as reducing the levels of water and air in the oil. Oil filtration is important for a variety of industries, including automotive, aviation, and industrial machinery, as it helps to ensure the proper functioning and longevity of machinery by preventing damage caused by contaminants in the oil. There are several different types of oil filtration systems available, including mechanical filters, centrifugal separators, and coalescing filters. The specific type of filtration system used will depend on the application and the type of oil being used.

Don’t change your oil, filter it!

Some model of cellulose depth filters manufactured around the world:1. A-Filters Inserts, B- Filters Inserts and more... 2.SDC1888, Water glycol filter SDPC 2088, cartridge sdc 1888 depth filters and more… 3.Destiny International - India, 200HE, 100 Series, 50 Series , 30 Series and equivalents 4.SDU-H350BM2, HDU-H300, SDU-H350RK , 2S-350-C4 , 4S-350-C8 , 6S-350-C12 , SDU-H8 , HDU-H8 , LDU-H8 , CFU-10 , CFU-10-PG , SDU-M8 , HDU-M8 , LDU-M8 , HDU-H8FL , HDU-H300FL2 , SDU-H8FL , SDU-H350BM2-FL , SDU-H8UW-S , SDU-H350UW-S

Destiny standout as the most reliable supplier & Manufacturer exporter of Hydraulic oil filtration machine, Hydraulic Off-Line Filtration Units, oil filtration machine in India, Hydraulic Oil Filtration Machine, Hydraulic Oil Cleaning System, Hydraulic Oil Cleaning System, Hydraulic Oil Cleaning, Hydraulic Oil Maintenance System, Turbine Oil Filtration Machine, Oil filtration systems manufacturer

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content

We respond quickly to emergency outages and situations – call us at (783) 878-1100