Case Study

Oil Cleaning Systems for Sheet Metal Component manufacturer

Location: North Punjab

Product Installed: Oil Filtration Machine

Application Background

10 YEARS OF CONSISTENT PERFORMANCE ON ISGEC PRESS

A reliability assessment is important in guaranteeing the precision, function, and use life span of any machinery. In this article reliability and performance of the Destiny make Lube oil filtration unit and its degradation was assessed to verify its effectiveness after 10 years of working on the ISGEC sheet metal working press.

In most circumstances, performance degradation is the main reason for machine failure and leads to a waste of product energy and time.

LOCATION –Sheet Metal Component manufacturer with ISGEC Straight-sided hydraulic press-North India, Punjab

OBJECTIVE-To access performance of Random, Dedicated filtration unit on ISGEC powerpack

Oil cleaning equipment Model – FOCUS 400 IN-Make-Destiny

Oil quantity of reservoir tank -1200 Ltrs

Machine commissioned Date – Jan 2011

Total clean oil machines with client -8 nos

Above Elementary Parameters Showed

- The customer was educated enough to understand cost-saving and machinery failures that could be prevented by maintaining oil cleaning standards.

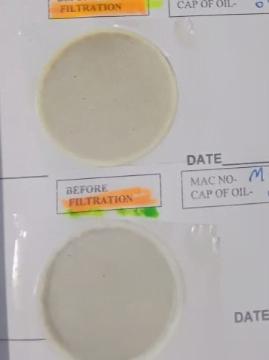

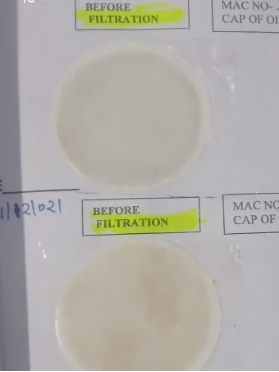

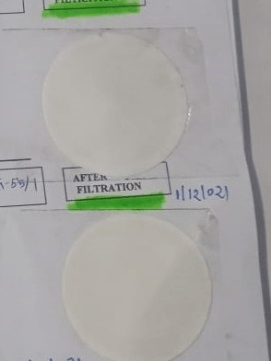

- Monthly oil patch testing ensured data logging and visible analysis of oil conditions.

- The customer was aware of the performance standard of the filtration unit and followed element change intervals to prevent degradation of oil.

- A dedicated unit on the power pack ensured no oil-related failures and also helped prevent unnecessary wear and tear of the oil-clean machine.

- Zero oil changes ensured carbon emission benefits and cost savings.

Solution

- Clean oil has become a necessity with the advent of low tolerance machinery. With benefits to overall productivity in industrial plants keeping clean oil has become a major part of machine maintenance.

- Destiny International with pride in Make in India is catering to domestic and international markets in the oil cleaning machine manufacturing segment.

- With excellent performance, awards from vendors for providing oil cleaning machines and services have made the brand to be proud for Made in India.

- High flow rate oil cleaning machines to compact filtration units make Destiny International a suitable solution for all types of oil cleaning applications.

Cost Savings

The filtration solution resulted in:

- 30% Reduction in Oil Replacement Costs: Cleaner oil meant less frequent replacements.

Decreased - Maintenance Costs: Fewer breakdowns and repairs led to lower overall maintenance expenses.

- Higher Productivity: The machine’s uptime improved, resulting in increased production output

The customer was aware that judgment can be made early to prevent machine failures basis oil analysis.

Oil Status Monitoring :

Installation :

100% Guaranteed Clean Oil