CASE STUDY

Contaminated Rust Preventive Oil

Application Background

A leading automotive component manufacturer was facing issues with their Rust Preventive (RP) oil used after machining and washing operations. RP oil is critical to protect parts from corrosion during storage and transport.

However, the oil started showing signs of contamination and was not delivering the required protection, leading to rejections and quality complaints.

Industry

Manufacturing / Heavy Engineering

Applications

Hydraulic presses, CNC machines, gearboxes, turbines, and other machinery using RP (Rust Preventive) Oil.

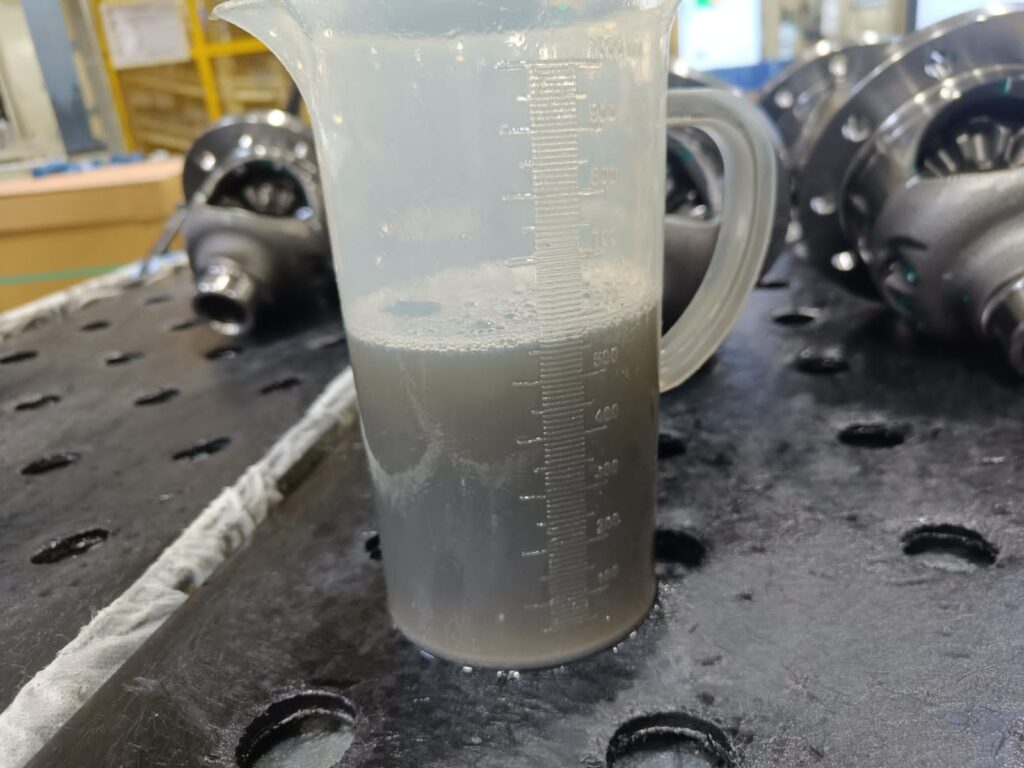

Oil Condition Before Filtration

The RP oil had been in use for 12–18 months without filtration.

Problem Statement

CONTAMINATION ISSUES:

1. Dust, dirt, metal particles, and sludge accumulation.

2. Moisture ingress during storage and handling.

3. Oxidation of oil leading to dark color and foul smell.

OPERATIONAL PROBLEMS FACED:

1. Reduced lubrication → higher wear & tear of components.

2. Frequent machine downtime due to oil-related issues.

3. Increased heat generation and energy consumption.

4. Poor corrosion protection due to loss of RP oil properties.

ROOT CAUSES :

1. Mixing of metallic fines & dust during handling.

2. Coolant carryover from machining/washing process.

3. Bacterial/fungal growth due to moisture.

4. Lack of proper filtration & monitoring system

COST IMPLICATIONS :

1. High oil replacement cost (buying new RP oil).

2. Increased maintenance cost due to component failure.

3. Production delays → revenue loss.

IMPACT ON OPERATIONS :

1. Increased rejections due to rust on precision components.

2. Customer complaints & warranty issues.

3. High replacement cost for contaminated RP oil.

4. Increased downtime in cleaning tanks & reprocessing parts.

SOLUTION APPLIED :

1. Installed Destiny’s filtration system.

2. Regular oil analysis program to monitor contamination, TAN (Total Acid Number), moisture, and particle count.

3. Scheduled tank cleaning & preventive maintenance.