Case Study

Bypass Hydraulic Oil Filtration System for Molding Machines

Location: North India

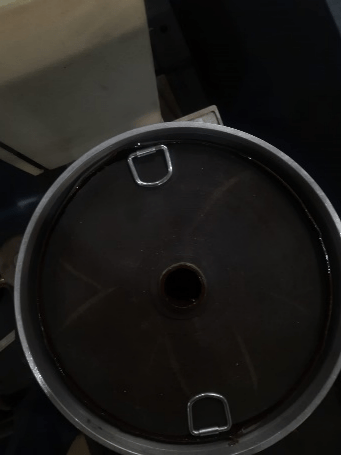

Product Installed: Bypass Hydraulic Oil Filtration System

Introduction

In the plastics manufacturing industry, molding machines rely heavily on hydraulic systems for precise operations. Ensuring the cleanliness of hydraulic oil is critical to maintaining optimal performance and extending the lifespan of equipment. This case study examines the implementation of a bypass hydraulic oil filtration system at (HIDDEN)Plastics, focusing on its benefits for molding machine efficiency and overall operational costs.

Application Background

(HIDDEN)Plastics specializes in producing high-quality plastic components through injection molding. The company faced significant challenges due to frequent hydraulic system failures, which resulted from contamination in the hydraulic oil. This led to increased maintenance costs and production downtime.

Challenges

- High Contamination Levels: Hydraulic oil was often found to have elevated contamination levels, affecting system performance.

- Frequent Downtime: Unscheduled maintenance due to hydraulic failures resulted in an average of 30 hours of downtime per month.

- Rising Maintenance Costs: The costs associated with oil changes and repairs were becoming unsustainable, threatening profit margins.

Objectives

- To reduce the level of contaminants in the hydraulic oil.

- To extend the life of hydraulic components and reduce maintenance costs.

- To improve overall machine reliability and operational efficiency.

Solution: Bypass Hydraulic Oil Filtration System

System Overview

Destiny’s bypass hydraulic oil filtration system operates independently, continuously filtering the hydraulic oil without interrupting the flow. This system is designed to capture fine particulates and water, improving overall oil cleanliness.

This system included:

- High-efficiency filters capable of removing particles as small as 1 micron.

- A pump that continuously circulates oil through the filtration unit without disrupting the main hydraulic operations.

- A monitoring system that tracks oil cleanliness and filter condition.

Implementation Process

- Selection of Filtration Technology: After evaluating multiple options, (HIDDEN) Plastics selected a high-efficiency bypass filtration system tailored for their molding machines.

- Installation: The system was installed with minimal disruption to production, completed in just one days.

- Training: Maintenance staff received comprehensive training to operate and monitor the new filtration system effectively.

Results

Performance Improvements

- Oil Cleanliness: Within one week, the average ISO cleanliness level of the hydraulic oil improved from ISO 24/20/17 to ISO 16/14/11.

- Reduced Maintenance: The frequency of filter changes was reduced by 50%, and the need for oil changes dropped by 30%.

- Extended Equipment Life: Components such as pumps and valves showed signs of reduced wear, extending their lifespan and lowering replacement costs.

Installation

Don’t change your oil, filter it!

Destiny standout as the most reliable supplier & Manufacturer exporter of Hydraulic oil filtration machine, Portable Hydraulic Oil Filter Machine, Oil Filter Cleaning Machine, Hydraulic Off-Line Filtration Units, oil filtration machine in India, Hydraulic Oil Filtration Machine, Hydraulic Oil Cleaning System, Hydraulic Oil Cleaning System, Hydraulic Oil Cleaning, Hydraulic Oil Maintenance System, online oil filtration system, Hydraulic system maintenance, Turbine Oil Filtration Machine, Oil filtration systems manufacturer, SERVO 460 Grade Oil Filtration Unit Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content,