Company Name: CNG CYLINDERS

Location:North India

Product Installed: Oil Filtration Machine – BU1200IN

Application Background

UNDER CAPACITY –OIL SKIMMING Belt Skimmer Oil Skimmer Manufacturer-A leading manufacturer of CNG CYLINDERS in India.

LOCATION-North India

The abstract of this case study is to highlight the importance of choosing the right filtration system, whether it be for any application, general or industrial.

In this case, the coolant system was using an OIL SKIMMER, a belt type with small belt width and other limitations.

The injection blow molding (IBM) process produces billions of plastic containers each year. Ranging in size from 1 ml to 2 litres, these containers meet exactly the standards of consistent weight, volume and tolerance, and are popular around the world for applications from pharmaceuticals to toiletries to automotive to household use and others.

FOCUS 400 IN FILTRATION UNIT INSTALLED FOR OIL CONTAMINATION REMOVAL

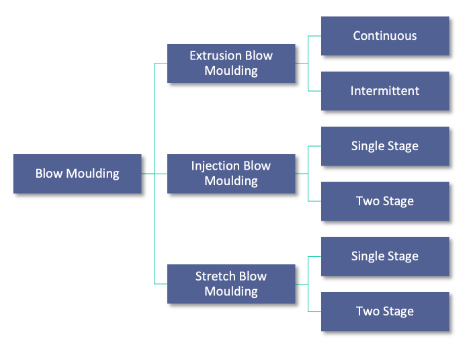

Types of blow molding machines

- Extrusion blow molding,

- Injection blow molding and

- Injection stretch blow molding.

MALFUNCTIONS ASSOCIATED DUE TO CONTAMINATED OIL & SOLUTION

Machine downtime is connected to the lifeblood of the machine that is hydraulic oil. This can be easily resolved by using correct ultrafine filtration or cleaning machines associated with depth filtration, which will remove routine moisture and contamination that has entered the system.

Focus portable cart -FOCUS 400 IN or Focus 800 IN, suits the purpose, making machine oil contamination related concerns to almost none.

Clean oil has become a must that can save owners a lot on the shutdown and maintenance costs. Oil cleaning has become a regimen in the blow moulding industry, with routine PMS being maintained.

MATERIAL USED FOR BLOW MOULDING PROCESS

Polyethylene (Low Density) | LDPE,LLDPE |

Polypropylene | PP |

Polyethylene – Terephthalate | PET |

Polyvinyl chloride | PVC |

Polyethylene (High Density) | HDPE |

RESULTS -OIL MAINTENANCE HEALTHIER MACHINES

FILTRATION MACHINE USED -FOCUS 400 IN/FOCUS 800 IN-MAKE-DESTINY

Discover Destiny’s® Unmatched Hydraulic Oil Filtration Solutions for IBM Machines!

As the leading supplier, manufacturer, and exporter in the industry, Destiny ensures optimal performance and longevity for your Injection Blow Molding machines.

- Superior Quality: Our filtration solutions are designed to enhance efficiency and reduce downtime.

- Expert Engineering: Tailored specifically for IBM machines, ensuring perfect compatibility and peak performance.

- Global Trust: Proven reliability with satisfied clients worldwide.

Contact us today to learn more and transform your manufacturing process with Destiny’s Hydraulic Oil Filtration Solutions.

Installation

Don’t change your oil, filter it!

Some model of cellulose depth filters manufactured around the world:1. A-Filters Inserts, B- Filters Inserts and more... 2.SDC1888, Water glycol filter SDPC 2088, cartridge sdc 1888 depth filters and more… 3.Destiny International - India, 200HE, 100 Series, 50 Series , 30 Series and equivalents 4.SDU-H350BM2, HDU-H300, SDU-H350RK , 2S-350-C4 , 4S-350-C8 , 6S-350-C12 , SDU-H8 , HDU-H8 , LDU-H8 , CFU-10 , CFU-10-PG , SDU-M8 , HDU-M8 , LDU-M8 , HDU-H8FL , HDU-H300FL2 , SDU-H8FL , SDU-H350BM2-FL , SDU-H8UW-S , SDU-H350UW-S

Destiny standout as the most reliable supplier & Manufacturer exporter of Hydraulic oil filtration machine, Hydraulic Off-Line Filtration Units, oil filtration machine in India, Hydraulic Oil Filtration Machine, Hydraulic Oil Cleaning System, Hydraulic Oil Cleaning System, Hydraulic Oil Cleaning, Hydraulic Oil Maintenance System, Turbine Oil Filtration Machine, Oil filtration systems manufacturer

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content

We respond quickly to emergency outages and situations – call us at (783) 878-1100