Coolant Tank Oil Skimmer is an integrated solution for keeping your coolant tank free of tramp oils. It saves you time and money by extending the life of your coolant and reducing coolant maintenance. During operation, it removes oil from the surface of the coolant, and deposits it into a collection container. Power can be supplied by the machine outlet on the control cabinet, or from any power outlet.

- Removes tramp oils directly from the coolant surface.

- Extends coolant life by minimizing bacteria growth.

- Plugs into the outlet of the machine, or into any outlet.

- Can use an electrical timer to control operation

The Oil Skimmer system is mounted above the liquid container, preferably on the opposite side of the liquid inlet. The outlet hose is attached to the outlet connection piece which is led into a setting tank. The device is connected to a power source of 220V.

The most common types include:

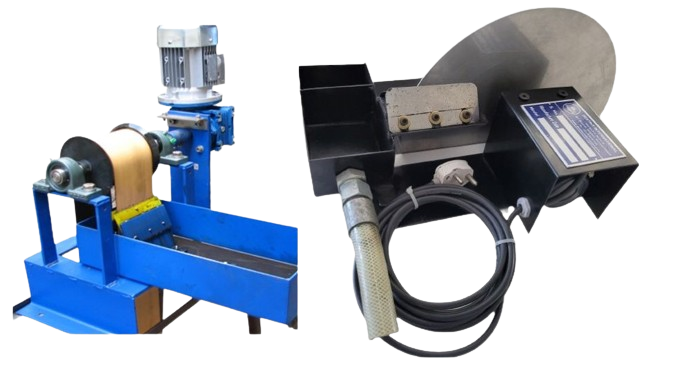

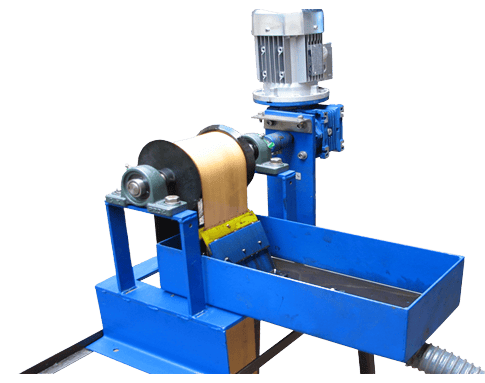

- Belt skimmers, which use a belt or chain to collect oil as it passes through.

- Disc skimmers, which use a rotating disc to collect oil as it passes through.

Our Products

- Oil Filtration Machines

- Hydraulic Oil Filtration Systems

- Electrostatic Liquid Cleaning (ELC) Machines

- Elc Collector-25c,50c,100c

- Low Vacuum Dehydration Unit (LVDH)

- Filter Cartridges

- Coolant Sump Cleaner

- By-Pass Filters

- Oil Transfer Unit

- Electrostatic Oil Filtration Machine

- Oil Analysis Equipment

- Contamination Cleaning Kit (CCK)

- Oil Skimmer

- Dedicated Motorised Filtration Unit

- HF series Filtration System-45LPM-54LPM

- Magnetic Oil Filtration Unit

- Highly Effective Filter Media

Applications:

- Soluble Cutting Oil

- Neat Cutting Oil

- Water Emulsion

- Quenching Oil

- CNC Machines

- Storage Tank

- Grinding

- VMC

- Hobbing

Destiny's Oil Skimmer :

- Belt skimmers, which use a belt or chain to collect oil as it passes through.

- Disc skimmers, which use a rotating disc to collect oil as it passes through.

Separating Oil From Coolant :

Will help reduce disposal costs. The cost of disposing of oil-laden coolant is more expensive than disposing of oil. In fact, in some instances, companies may be able to re-use the oil elsewhere or sell it for recycling. Having oil free coolant can also extend its usefulness and effectiveness, reducing the expense on maintenance and coolant replacement. As the research on the different types of oil skimmers begins, a person will find that there are a variety of skimmers available to them. Separating oil from water based coolants has been made easy by oil skimming equipments.

Skimmer Types:

Using a belt skimmer are as follows. With its compact size, it requires very little operating space. Belt skimmers have good oil pick up rates (up to 20lph depending on belt width). This type of skimmer can handle fluctuating coolant levels while still maintaining minimal operating space and maximum pick up capacity.

The Disk Skimmer provides an inexpensive way to remove unwanted tramp oils from CNC coolants and parts washers. Disk skimmers can offer a slightly more cost-effective and higher pick up rate compared to belt skimmer.However disk skimmer equipment requires a larger operating space to accommodate the disk and a steady fluid level for optimal efficiency

100% Guaranteed Clean Oil