Studies have shown that for each grade the ISO code is lowered, the life of a hydraulic component can be doubled or tripled..

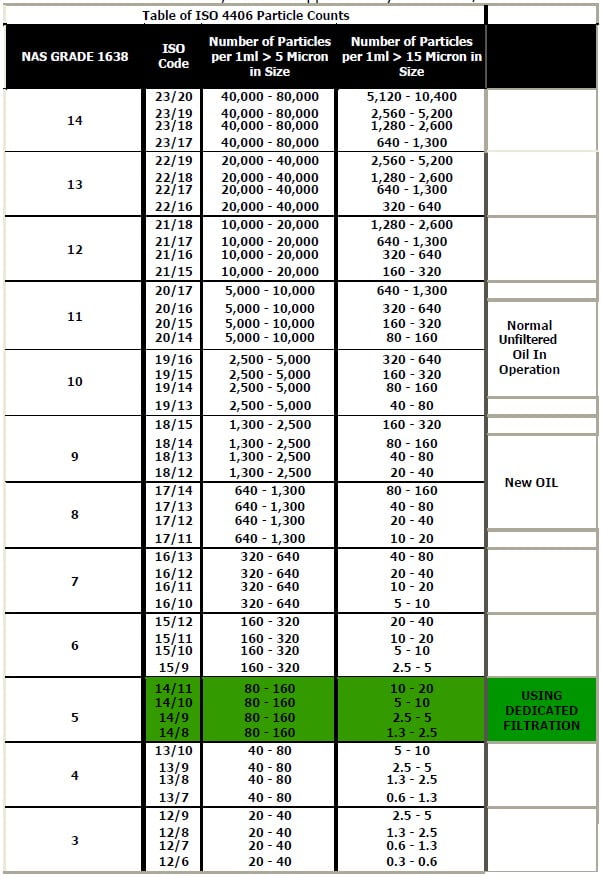

As shown in the chart, new oil is approximately rated at 18/15

Questions ?

Can’t find what you’re looking for?

When oil analysis samples are submitted to particle counting, automatic particle counting (APC) is typically used — the current calibration standard for APC is ISO 11171. In APC, particles are counted through either laser or pore blockage methods. Different laboratories may report different particle count micron levels. As an example, a lab report may include levels greater than 4, 6, 10, 14, 21, 38, 70 and 100 microns.

ISO 4406:99 is the reporting standard for fluid cleanliness. According to this standard, a code number is assigned to particle count values derived at three different micron levels: greater than 4 microns, greater than 6 microns and greater than 14 microns. The ISO code is assigned based upon Table 1. This can be seen in the example on the left.

However, without seeing the raw data, the only thing the ISO code can positively identify is whether a sample has achieved the desired target value. The ISO code does nothing to help determine any real trend information unless the value of the raw data at the given micron levels changes enough to raise or lower the ISO code.

The unit of measure for particle count data is “particles per milliliter of sample.” The particle counters used in laboratories incorporate much more than a milliliter of sample: approximately 100 milliliters of a sample are taken into the instrument during the testing process. The numbers of particles are counted based on this value. The total number of particles is then compared to the number of times that two will go into that total count exponentially.

Why is cleanliness so important? The answer is simple: competition. In such a globally competitive market, where products can potentially be manufactured and shipped from overseas at a lower cost, maintaining a precise level of reliability and uptime is necessary to keep costs manageable. Contaminant-free lubricants and components will extend the lifetime of both, and in turn, increase the overall reliability of the equipment. Solutions like SKF RecondOil’s Oil as a Service can be an ally in the battle against contamination, simplifying the process of reaching your ISO cleanliness targets.

Using the previous example (20/17/13), this means that at the greater than 4-micron level, the number of particles measured was at the most 2^20 and above 2^19. Since particle count data is reported in particles per mL of sample, the raw data must be divided by 100.

While the general rule is that for every increase in the ISO cleanliness code, the number of particles has doubled, this certainly is not the case in every situation. Because the number of allowable particles doubles within each code number, it is possible for the number of particles to increase by a factor of four and only increase a single ISO code.

FOCUS 400-IN

FOCUS 800-IN

FOCUS 1200-IN

FOCUS 1600-IN

Don’t change your oil, filter it!

Can’t find what you’re looking for?

Contact Us for overarching Solutions

Experience our top-notch filtration Ultra-fine Oil Filtration Machine to collect all types and sizes of contaminants. It remove all types of particles such as wood, plastic, paper,metal wear, and rubber.

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content