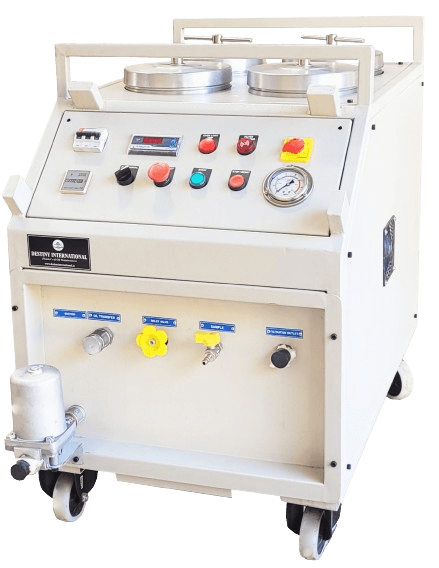

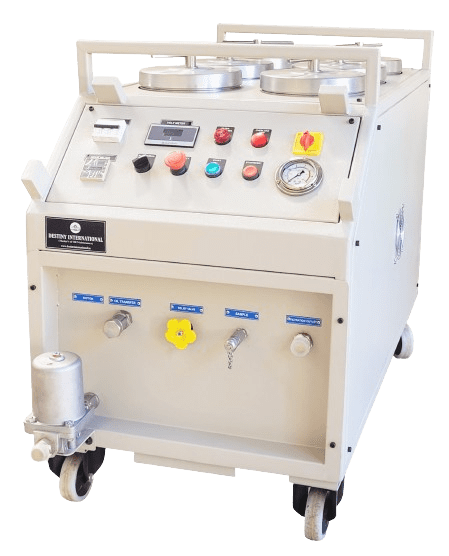

HYDRAULIC OIL FILTRATION MACHINE

Hydraulic Oil Filtration Machine & Oil Filtration Equipments in India

Destiny’s® FD/FP Series Oil Filtration Systems are high end technology machines popularly used for Ultra-Fine Stage Filtration (fine solid particle removal) of lubricating and hydraulic oils.

Discover our high-quality products designed to meet your specific needs

Our range includes advanced filtration systems, cutting-edge oil cleaning solutions, and reliable maintenance equipment.

Each product is meticulously engineered to deliver superior performance, ensuring optimal efficiency and cost-effectiveness for your operations.

Our Oil Filtration Machine is a multi-purpose fluid cleaning machine that can clean most oils such as hydraulic oil, gear oil and many soluble oils and fluids. More than 85% of hydraulic oil failures are caused by contaminants in the oil.

Meeting Our Hydraulic Systems’ High Oil Purification Standards

How Important is Fluid Filtration in a Hydraulic System?

A hydraulic system is a complicated network of components, hoses, valves, and piping which are commonly found in any heavy-duty machinery. These systems may be diverse in terms of how they operate, but their basic operating principle remains the same – generating force through non-compressible fluids.

Hydraulic systems are commonly found in the steering wheels of a vehicle or applications used for heavy lifting of weights. A hydraulic system is a mechanical process, therefore, it’s vulnerable to regular wear and tear. Some of its components like springs and seals become loose due to leakages and poor fluid filtration. Fluid contamination is considered to be one of the main reasons for the failure of hydraulic systems according to industry experts.

Selecting the right kind of hydraulic oil filter cart is very important. There are lots of variants available in the market right now. It’s advised to consult your original equipment manufacturer OEM before buying a certain fluid as it depends on the kind of device you have. For most of the applications, petroleum-based oil fluids are generally recommended by the experts. Water-oil emulsions, water-glycol, and synthetic hydraulic fluids are also utilized for fire-resistant fluids.

Hydraulic Oil Machine Application

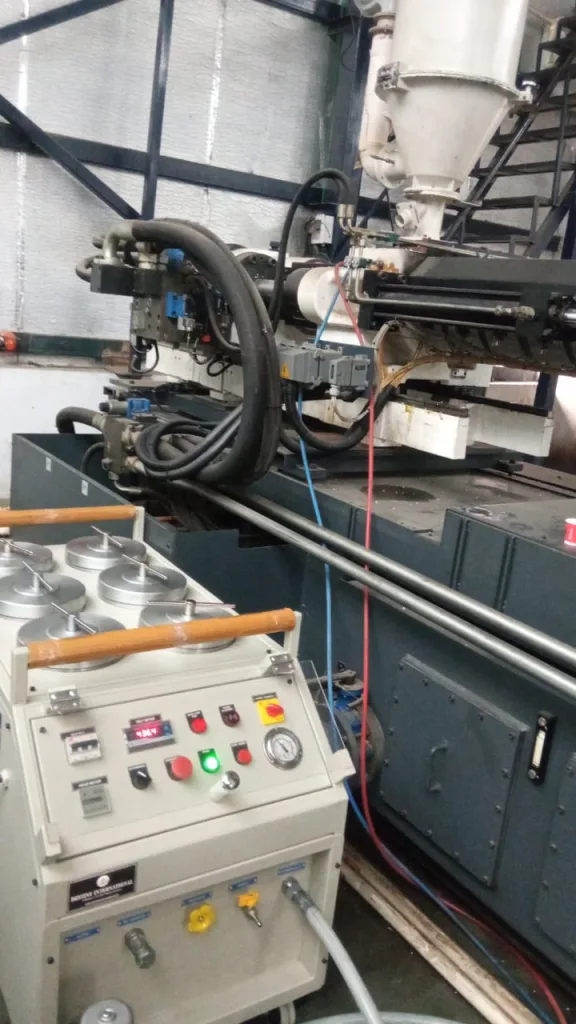

- Injection Molding Machines

- Die Casting Machines

- Blow Moulding Machines

- Power Press

- Excavators

- Dumpers

- Crane

- Hydraulic Power Packs

Steps to maintain a functional hydraulic oil filtration machine:

- The area around the reservoir must be neat and clean.

- Conduct proper flushing of all systems before preliminary starting.

- When the new equipment achieves its break-in period, change fluids and hydraulic filters.

- The reservoir must have a quality breather attached to it.

- Make sure that the fluid being added must reach the exact specifications during addition.

- Filter all the fluid down the reservoir periodically with the help of an A-Grade hydraulic filter cartin the form of a kidney loop.

- Perform fluid analysis tests regularly especially after suspecting contamination.

- Ensure that your team utilizes standard Beta 1000 elements in every filter housing, and replace them when required.

- Make sure that the hydraulic hoses are plugged in well while repairing the system.

- Always repair leakages as early as possible.

Oil Filtration Machine Focus 400-IN

Oil Filtration Machine Focus 800-IN

Oil Filtration Machine Focus 1200-IN

Oil Filtration Machine Focus 1800-IN

RESULT

For all of our services, we bring a Hydraulic Oil Filtration Machine, Hydraulic Oil Filtration Unit and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance (achievement of specified ISO cleanliness levels and moisture content

- Soluble Cutting Oil

- Neat Cutting Oil

- Water Emulsion

- Quenching Oil

- CNC Machines

- Storage Tank

- Grinding

- VMC

- Hobbing

- Filter Media-wood pulp paper

- Filter efficiency 0. 1 microns

- Cartridge is made of densely wound pure coniferous long fiber wood pulp paper

• Less power consumption – Uses a single-phase vacuum pump

• Offline coolant filtration system – for multiple cycles of filtration

• Portable and safe – the unit is on wheels, curbing chances of injury

• Faster cleaning process due to vacuum suction

• Robust construction

• Antibacterial residual filtering system

• Improves quality of coolant and ultimately products being machined

• Filters upto 10 microns particle size

• Cleaning process in very short time. E.g.: 10 to 15 minutes for base model

- These are the most common mistakes with hydraulic machinery make, and how you can avoid them.

- Changing the filters on hours… .

- Only change when 80% of the dirt holding capacity has been reached.

- Running too hot… .Keep it cool! Stay below 60˚C for hydraulic oil!

- Disregard the start-up check list… .

- Always act according to your machines’s start-up check list!

- Changing the oil on hours…

- Keep it clean and have it analyzed first!Using the wrong oil… .

- Check what viscosity grade fits your machine requirements the best!

- Wrong filter locations… .

- Avoid a suction strainer at the pump inlet!

- Consultation – Assess and identify the right system for you

- Water Filtration – Remove 100% water contamination. Water contamination can reduce the life of machinery by more than 50%

- Particle Filtration – Remove contamination down to 0.1 micron (3 absolute)

- Oil Analysis Reports – Enable us to assess the effectiveness of your filtration, cooling systems and identify failing components.

- Improvement Plan – Practical suggestions to help you reduce contamination before it happens.

Don’t change your oil, filter it!

Can’t find what you’re looking for?

Contact Us for overarching Solutions

Experience our top-notch filtration and oil cleaning solutions designed to meet your specific needs.

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations.For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content

Destiny standout as the most reliable supplier manufacturer exporter of Ultra Fine Hydraulic Oil Filtration Systems, hydraulic off-line filtration units, oil filtration machine in India, hydraulic oil filtration machine, portable oil filtration systems, portable oil filtration machine, Hydraulic Oil Filtration Unit, Ultra Fine Hydraulic Oil Filtration Machine Manufacturer In India