Case Study - Hydraulic Depth Filters

FILTERS that use a porous medium and catch particles using throughout the medium and not just the surface or layer. Medium can be fibrous cellulose, polypropylene along with base paper or flat filter cloth. It normally will have an inner core an outer core, in some case, a shoot to encase the media.

There is normally a base paper or filter cloth to act as a bed to flow of liquid through the media.

Filter extraction hooks /ribbon/or eyelet help removal of filter after it has choked or used.

Depth Filters

- CELLULOSE PAPER DEPTH FILTERS

- POLYPROPYLENE DEPTH FILTERS

- CELLULOSE PAPER DEPTH FILTERS

Developed to increase oil change intervals half a decade back-the method is used worldwide for ultrafine cleaning of machine oils.

Hydraulic oil cleaning is blessed with usage of depth filtration, keeping machines well oiled and never prone to failures.

Long slender fiber pulp are used for making filter paper used for depth filters. Long fibers help absorb moisture, and the capillary action of the fibers help retain moisture in media. The round coil similar to a paper roll from a depth and various level of compression on outer core enable multi layer filtration assisted by base paper, skirting or other arrangement as per manufacturer designs.

Table for clearance Between Filter Condition & Preventives Indications

FILTER CONDITION | PREVENTIVES/INDICATIONS |

DUST DEBRIS AND VISIBLE CONTAMINANTS | NORMAL OPERATING AND OIL CONDITION. CHECK TAN <1 |

LARGE QUANTITY OF CONTAMINANTS ON FILTER SURFACE. | INSPECT MACHINE AT THE EARLIEST, WEARING /ERODING OF MACHINE INTERNAL EXPECTED. |

CRACKS ON FILTER LAYERS AND SPONGY AND SOFT | INDICATION OF MOISTURE OR HEAT EXCHANGER OR ACCIDENTAL INGRESS OF WATER.HIGH ALERT REQUIRE IMMEDIATE ATTENTION AND SOLUTION. |

FILTER IS HARD WITH VISIBLE DIRT AND CRACKS. | FILTER REPLACEMENT REQUIRED, REACHED SATURATION. |

SHRINKAGE OF FILTER | CHECK FOR HIGH PRESSURE EXPOSURE TO FILTER |

VISIBLE PRESENCE OF METAL | GO FOR OIL ANALYSIS INTERNAL COMPONENT WEAR EXPECTED |

FILTER APPEARS CLEAN | CHECK IF CHECK VALVE IS MALFUNCTIONING, PREVENTING OIL INLET TO FILTER. |

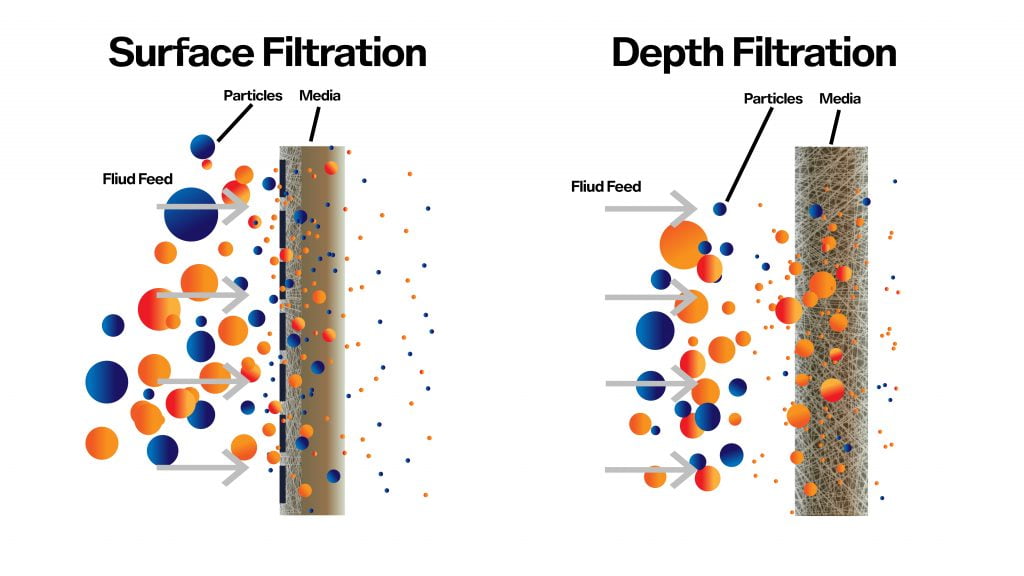

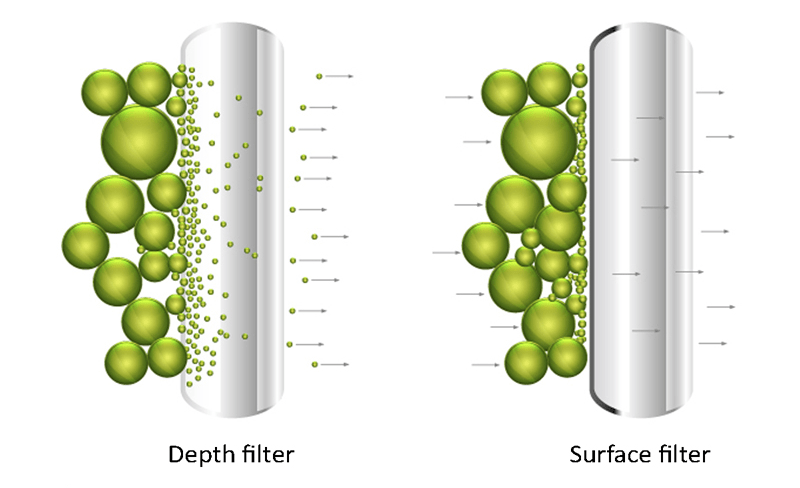

The amount of surface area directly correlates to the solids loading capability and related pressure drop. Depth Filtration refers to a thicker media or multiple layers of media, forming a torturous path to retain particles.

FLOW DIAGRAM OF SURFACE FILTER VS DEPTH FILTER

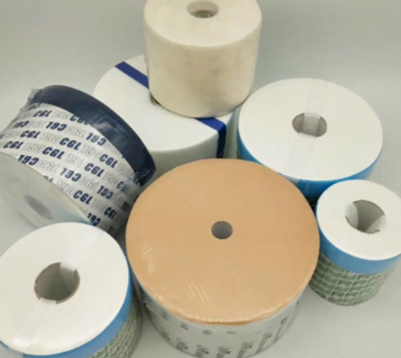

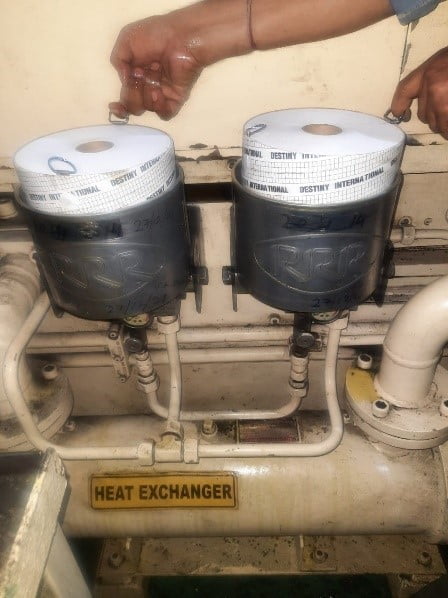

Designs Photos Of Depth Filters Used In Industries Housing With Replacement Filters

FILTER CARTRIDGE

DEPTH FILTER ELEMENT TYPE -3

FILTER ELEMENT

EVIDENCE OF DELAYED FILTER CHANGES

EVIDENCE OF DELAYED FILTER CHANGES

EVIDENCE OF DELAYED FILTER CHANGES

Some model of cellulose depth filters manufactured around the world:

M-Series, E- Series, E-Series and more…

A-Filters Inserts, B- Filters Inserts and more…

SDC1888, Water glycol filter SDPC 2088, cartridge sdc 1888 depth filters and more…

Destiny International – India, 200HE, 100 Series, 50 Series , 30 Series and equivalents

SDU-H350BM2, HDU-H300, SDU-H350RK , 2S-350-C4 , 4S-350-C8 , 6S-350-C12 , SDU-H8 , HDU-H8 , LDU-H8 , CFU-10 , CFU-10-PG , SDU-M8 , HDU-M8 , LDU-M8 , HDU-H8FL , HDU-H300FL2 , SDU-H8FL , SDU-H350BM2-FL , SDU-H8UW-S , SDU-H350UW-S

SUPER DUTY FILTER CARTRIDGE

EVIDENCE OF METAL WEAR IN MACHINE

EVIDENCE OF METAL WEAR IN MACHINE

EVIDENCE OF METAL WEAR IN MACHINE

POLYPROPYLENE DEPTH FILTERS

POLYPROPYLENE DEPTH FILTERS

FACTORS TO DETERMINE PERFORMANCE OF DEPTH FILTERS

| Beta ratio | Yes |

Efficiency | Yes |

Dirt holding capacity | Yes |

Moisture absorbing capacity | Yes |

Micron rating | Yes |

| Dimensions | Yes |

CGL Filter , CGL Filter ME30,CGL Filter ME32,CGL Filter ME50,CGL Filter ME100 Triple R Filter Yupao Filter ,YUPAO BYPASS OIL FILTER BU 30 Bypass Oil Filter Filtroil BU 200HE , filtroil 200he, Hydraulic Filter ElementM-Series, E- Series, E-Series and more...

Don’t change your oil, filter it!

Can’t find what you’re looking for?

Contact Us for overarching Solutions

We manufacture any size of cellulose filter in any quantity from its HQ in India : with a wide network offering filtration system as a direct installation or mobile unit to suit any application. Even in the most aggressive environments, Destiny International can address the issues of moisture, particulate, varnishing, component failures due to poor oil hygiene.

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations. For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance achievement of specified ISO cleanliness levels and moisture content