Filtration of oil in auto as well as industrial machinery are very essential to get best results, reliability and longevity. Cleaning lubricant is extremely important & lubrication practitioner are equipped with different options for filtering and controlling contamination, including disposable filters, cleanable filters, strainers and centrifugal separators.

While it’s extremely true to have conventional mechanical filters which can remove many particles in the same size & range as magnetic filters, the majority of filters are disposable and incur a price for every gram of particles removed.

Oil filtration in automotive and industrial machinery is essential to achieving optimum performance, reliability and longevity. Lubricant cleanliness is highly important, and lubrication practitioners are provided with numerous options for filtering and controlling contamination, including disposable filters, cleanable filters, strainers and centrifugal separators..

TRUMAG-MODEL | NOS OF (1 INCH OD RODS)WITH LENGTH | FLOW RATE | HOLDING CAPACITY | IN/OUT CONNECTION |

8X1 | 1 NOS -8 INCH EACH | 50LPM | 0.8 KG | I NCH |

8X2 | 2 NOS -8 INCH EACH | 100LPM | 1.5 KG | 1 INCH |

16X3 | 3 NOS -16 INCH EACH | 250 LPM | 4.5 KG | 2 INCH |

16X4 | 4 NOS -16 INCHEACH | 250 LPM | 6.5 KG | 2 INCH |

1. Gearbox (includes final drive, differential) both forced-circulating & splash fed

2. Any machine with ferrous frictional surface but with no forced oil circulation & filtrations

3. Applications where different use of magnetic filters will substantially stretch the life of conventional old filters already in use

4. Applications where iron particles are known to be a high contributor to oil oxidations problem

5. Hydraulic systems, particularly those using electrohydraulic valves

6. In situations requiring better precision in recognizing abnormal wear particle generation (and wear particle type)

1. Reusable Technology, the value of removing a little tiny particle from the oil with magnetic technology is low compared to disposable filters.

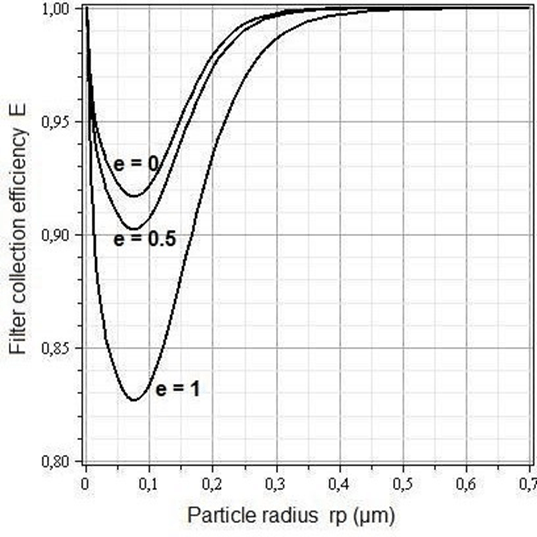

2. Limited Flow Restriction, unlike conventional filters, most magnetic filters exhibit little to no increase in flow restriction (pressure drop) because it loads with particles.

3. Extended Life of Conventional Filters, when used in collaboration with old & conventional mechanical filters an increase in effective filter service life 2-3 times may be experienced.

4. Lower Risk of Oil Oxidation, Iron & steel particles can be easily known to promote all oil oxidation by their catalytic property. Premature oil oxidation can lead to acute varnish, high sludge & extreme corrosion. Magnetic filters usually have a +ive impact on oil service life, & over the time it reduces oil consumptions if it is changed on condition.

5. Enhanced Wear Particle Identification, particles removed from magnetic rods & magnetic filters are often in their pure state which can extremely enhance the accuracy of machine condition analysis.

6. Quick Wear & tear of Metal Inspections, Rods can be removed for several visual inspections (daily, weekly) without stopping any machine or removing the filter. They provide a dual service of contaminants removal & conditions monitoring (from the density of wear particles).

TRUMAG-MODEL NOS OF (1 INCH OD RODS) WITH LENGTH FLOW RATE HOLDING CAPACITY IN/OUT CONNECTION

- Grinding Honing, Lapping &Shaving Machines

- Pre-Filtration

- Fine Finishing Operations

- Wire And Edm Process

- Injection Moulding Cooling And Heating Systems

- Industrial Part Washing

- Quenching Operations

- Manual And Cnc Machining

- Food Industry

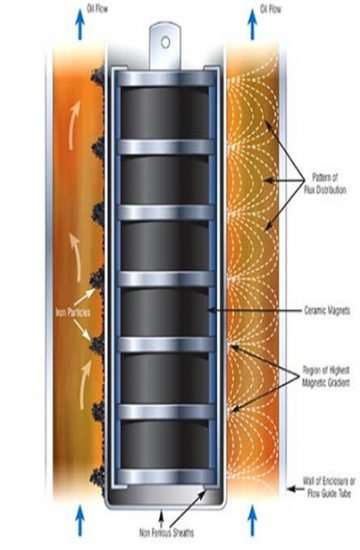

Magnetic Filtration UNIT

For all of our services, we bring a Particle Counter and Portable Fluid Analysis Kit onsite to analyze oil samples and document our performance (achievement of specified ISO cleanliness levels and moisture content...

Can’t find what you’re looking for?

Questions ?